Copper vs Aluminium Bronze: Choosing the Right Non-Sparking Tool Material

In industries where flammable gases, vapors, or combustible dust create potentially explosive atmospheres, the simple act of using a standard steel tool can become a deadly mistake. When metal strikes metal or stone, the friction generates sparks that can reach temperatures exceeding 1,800 degrees Celsius—more than hot enough to ignite volatile substances and trigger catastrophic explosions. This harsh reality makes non-sparking tools not merely a recommendation but an absolute necessity in hazardous work environments. Understanding the materials that make these safety tools effective is crucial to protecting lives and facilities.

Understanding Non-Sparking Tools and Their Critical Importance

Non-sparking tools represent a specialized category of safety equipment designed to prevent ignition in explosive atmospheres. Unlike conventional steel tools that generate sparks through impact or friction, these tools are manufactured from specific non-ferrous metal alloys that possess dramatically reduced spark generation potential. The fundamental principle behind their operation lies in material science: the alloys used are softer than steel and, when struck, tend to deform rather than fracture, thus preventing the high-energy particle release that creates visible sparks.

The applications for non-sparking safety tools span across multiple high-risk industries. Oil and gas operations, including refineries, drilling platforms, and pipeline maintenance, demand these tools wherever hydrocarbon vapors might be present. Chemical processing plants handling volatile solvents and reactive compounds cannot safely operate without them. Mining operations extracting coal or working in environments with methane accumulation require sparkless tools to prevent underground explosions. Pharmaceutical manufacturing, where organic solvents are routinely used, and paint manufacturing facilities where flammable vapors pervade the atmosphere, both mandate the use of explosion-proof tools.

Regulatory frameworks worldwide recognize the critical nature of this safety equipment. Standards established by OISD (Oil Industry Safety Directorate), ATEX (Atmosphères Explosibles), OSHA (Occupational Safety and Health Administration), and NFPA (National Fire Protection Association) mandate the use of non-sparking tools in various oil and gas applications and explosive atmospheres. In India, IS 4595 standards specifically govern the non-sparking properties of safety tools, ensuring they meet rigorous performance criteria. Compliance with these regulations isn't optional—it represents the minimum acceptable standard for protecting workers and facilities from ignition hazards.

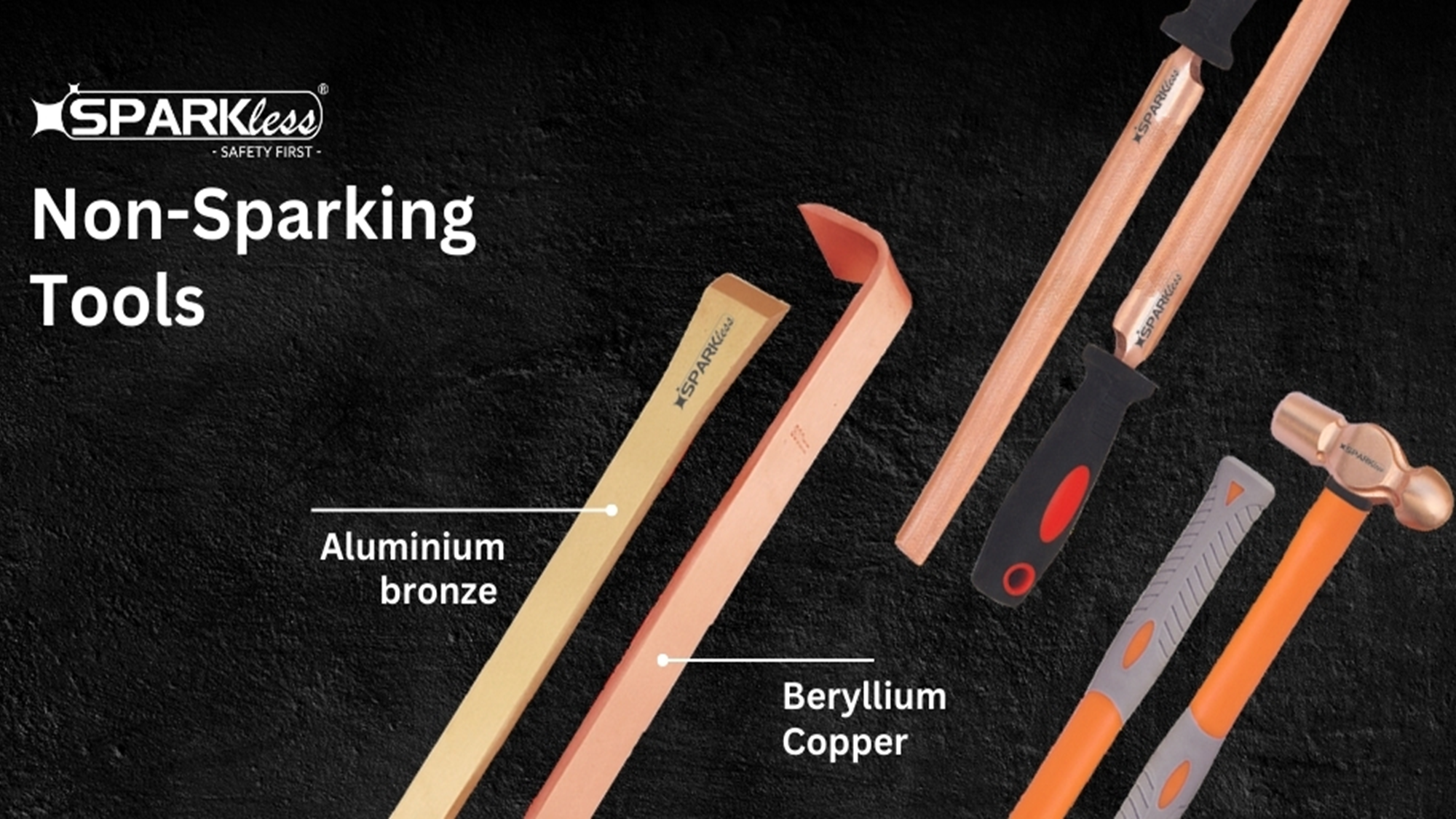

The Two Primary Alloys: Copper Beryllium and Aluminum Bronze

When selecting non-sparking hand tools, you face a fundamental choice between two primary alloy families: copper beryllium (also called beryllium copper) and aluminum bronze. Each material brings distinct characteristics that make it suitable for different applications and environments. Understanding these differences enables informed decisions that balance safety requirements, performance needs, and budget considerations.

Copper beryllium represents the premium option in non-sparking tool materials. This alloy typically contains approximately 98% copper combined with 2% beryllium, though the exact composition may vary slightly depending on the manufacturer and specific application requirements. The addition of beryllium to copper creates remarkable properties that set this material apart. Copper beryllium offers superior hardness, durability, and broader zone compatibility, making it ideal for more critical and hazardous environments. The beryllium component enables the copper to achieve strength levels approaching those of steel while maintaining the non-sparking characteristics essential for safety.

Aluminum bronze, by contrast, consists primarily of copper alloyed with aluminum, typically in concentrations ranging from eight to twelve percent, along with smaller amounts of iron, nickel, manganese, or other elements that enhance specific properties. This material has been used for decades in marine applications, chemical processing equipment, and other environments where both corrosion resistance and strength are required. Aluminum bronze serves as an alternative metal for non-sparking tools, offering reliable safety performance at a more accessible price point than copper beryllium.

Hardness and Strength: Where Performance Differences Emerge

The mechanical properties of non-sparking tools directly impact their effectiveness in demanding applications. When you're applying torque to stubborn fasteners or striking chisels with heavy impact, the tool material must withstand these forces without deforming excessively or failing. This is where the differences between copper beryllium and aluminum bronze become most apparent.

Aluminum bronze demonstrates high strength for torque and impact situations, with a Brinell hardness ranging from 200 to 350 and tensile strength between 95,000 to 150,000 psi. These specifications indicate that aluminum bronze tools can handle substantial mechanical stress and are suitable for most routine maintenance and operational tasks in hazardous environments. The material provides adequate durability for regular use while maintaining its non-sparking properties throughout its service life.

Copper beryllium tools, however, operate at an even higher performance level. Beryllium copper has maximum strength for torque and impact situations. While aluminum copper has a hardness of 22-29 HRC, beryllium copper tools are slightly harder at 28-36 HRCs. This superior hardness translates to better edge retention in cutting tools, reduced wear in frequently used implements, and the ability to apply greater force without tool deformation. For applications involving substantial torque requirements or heavy impact work, beryllium copper's enhanced mechanical properties provide a significant operational advantage.

The strength difference becomes particularly relevant in heavy-duty applications. When breaking loose corroded bolts, striking cold chisels against hardened surfaces, or applying maximum leverage with wrenches and pry bars, the additional strength of beryllium copper prevents tool failure and extends service life. This performance advantage means that while beryllium copper tools cost more initially, they may actually prove more economical over time in demanding applications due to their extended durability.

Zone Classification and Material Selection

Understanding hazardous area classifications helps clarify which non-sparking tool material best suits your specific operational environment. Industrial facilities with explosive atmosphere potential are classified into zones based on the likelihood, frequency, and duration of explosive atmospheres. These classifications guide safety equipment selection, including the appropriate non-sparking tools.

Working in a variety of zones requires the use of different alloys because of the various types of combustibles present in the atmosphere, such as dust, gas, and vapors. Zone 0 areas, where explosive atmospheres are present continuously or for long periods, demand the highest safety standards. Zone 1 areas, where explosive atmospheres are likely to occur during normal operations, also require robust safety measures. Zone 2 areas, where explosive atmospheres are unlikely and would only persist briefly if they do occur, may allow somewhat less stringent requirements.

Copper beryllium tools are certified for use across all hazardous zone classifications, making them universally applicable regardless of the specific explosive atmosphere risk level. This broad compatibility makes beryllium copper the preferred choice for facilities with multiple hazard zones or where tools might be used across different classified areas. The material's superior performance characteristics ensure it meets the most stringent safety requirements in the most demanding environments.

Aluminum bronze tools, while effective non-sparking implements, may have limitations in certain zone classifications or with specific combustible materials. This doesn't mean they're unsafe—rather, they're optimally suited for less critical applications or environments where the explosive atmosphere risk is lower. For many maintenance operations in Zone 2 areas or facilities handling less volatile substances, aluminum bronze provides entirely adequate safety performance at a reduced cost.

Corrosion Resistance and Environmental Durability

The harsh environments where non-sparking tools see service often involve more than just explosion hazards. Chemical exposure, moisture, salt spray, extreme temperatures, and contamination from various substances can all degrade tool materials over time. Corrosion resistance therefore becomes an important consideration when selecting between copper beryllium and aluminum bronze options.

Both alloy families offer excellent corrosion resistance compared to steel tools, but their performance in specific environments varies. Aluminum bronze exhibits outstanding resistance to seawater corrosion, making it particularly well-suited for offshore oil platforms, marine petrochemical facilities, and coastal refineries. The aluminum content forms a protective oxide layer that shields the underlying metal from further corrosion, even in highly corrosive marine atmospheres.

Copper beryllium also provides good corrosion resistance across a broad range of chemical exposures. The alloy performs well in petroleum environments, resists attack from most organic solvents, and maintains its integrity when exposed to many industrial chemicals. However, both materials require proper maintenance and cleaning to preserve their protective characteristics and ensure continued non-sparking performance.

Environmental contaminants can compromise the non-sparking properties of these tools if allowed to accumulate on working surfaces. Rust particles from steel equipment, embedded steel fragments from contact with ferrous materials, or buildup of hardened deposits can all potentially create spark hazards. Regular cleaning and inspection ensure that safety tools maintain their protective characteristics throughout their service life. Tools should be cleaned after each use, particularly if exposed to contaminants, and stored in clean, dry conditions that prevent corrosion.

Cost Considerations and Value Assessment

The financial aspect of non-sparking tool selection involves more than just comparing initial purchase prices. While cost certainly factors into procurement decisions, a comprehensive value assessment considers tool longevity, performance capabilities, maintenance requirements, and the potential consequences of tool failure or inadequate safety equipment.

Compared to steel tools, beryllium copper tools are more expensive and not as strong, but the properties of beryllium copper in hazardous environments may outweigh the disadvantages. This observation highlights the fundamental trade-off: non-sparking tools sacrifice some mechanical strength compared to steel, and premium non-sparking materials like beryllium copper command higher prices. However, in explosive atmospheres, the safety characteristics of these materials become paramount, and their cost must be evaluated in that context.

Aluminum bronze, while less hard and durable, still provides a cost-effective and reliable solution for less demanding applications. For organizations equipping large maintenance crews or building comprehensive tool inventories, aluminum bronze offers an economical path to compliance with safety regulations. The material performs reliably in most routine applications, and its lower cost enables broader tool availability throughout an organization.

The true cost comparison must factor in tool lifespan and replacement frequency. Beryllium copper's superior hardness and wear resistance mean these tools typically last longer under heavy use. For frequently used implements or applications involving high stress, the premium tool may actually prove more economical over its service life despite the higher initial investment. Conversely, for tools used occasionally or in lighter-duty applications, aluminum bronze's cost advantage makes it the more economical choice.

Organizations should also consider the cost of inadequate safety equipment. A tool that fails during a critical operation, forcing workers to use improvised alternatives or delay essential maintenance, can create safety risks and operational disruptions far exceeding any purchase price savings. Similarly, the catastrophic cost of an explosion triggered by inadequate safety equipment makes the investment in proper non-sparking tools one of the most economically justified safety expenditures any hazardous facility can make.

Practical Selection Criteria for Your Operations

Choosing between copper beryllium and aluminum bronze non-sparking safety tools requires evaluating several factors specific to your operational context. This decision framework helps align material selection with actual working conditions and requirements.

Begin by assessing the hazard classification of work areas where these tools will be used. If operations span multiple zone classifications or involve particularly hazardous materials with low ignition energies, beryllium copper's broader compatibility and superior safety margins provide valuable assurance. For work primarily in Zone 2 areas or with less volatile substances, aluminum bronze may sufficiently meet safety requirements.

Consider the mechanical demands of your typical applications. Heavy-duty operations involving high torque, substantial impact forces, or frequent use of cutting edges benefit from beryllium copper's enhanced hardness and strength. Routine maintenance tasks, light assembly work, or occasional use applications may not require the premium material's performance characteristics.

Evaluate your budget constraints realistically. If financial limitations would result in an inadequate inventory of proper tools, causing workers to occasionally resort to conventional steel implements, aluminum bronze's lower cost enables more comprehensive tool availability. A complete set of aluminum bronze tools provides better safety than a partial set of beryllium copper implements supplemented by dangerous improvisations.

Environmental factors also influence material selection. Marine environments or operations involving significant saltwater exposure favor aluminum bronze's exceptional corrosion resistance. Chemical processing involving specific aggressive substances may perform better with one alloy over the other, and reviewing compatibility charts for your specific chemicals helps inform this decision.

Maintaining Non-Sparking Tools for Continued Safety

Even the highest quality non-sparking hand tools require proper maintenance to preserve their safety characteristics and operational effectiveness. Establishing and following maintenance protocols ensures these critical safety implements continue protecting workers throughout their service life.

Cleaning represents the most fundamental maintenance requirement. After each use, tools should be wiped clean to remove contaminants, particularly any steel particles that might have transferred from contact with ferrous materials. Periodic thorough cleaning with appropriate solvents removes accumulated deposits and allows inspection of the tool surface. Avoid abrasive cleaning methods that might embed particles into the soft alloy or damage the tool surface.

Regular inspection catches problems before they compromise safety. Examine working surfaces for embedded foreign particles, particularly steel fragments that could generate sparks. Check for excessive wear, deformation, or damage that might affect tool function or create sharp edges where steel contamination could lodge. Cracks, deep scratches, or severe deformation warrant removing the tool from service even if it appears superficially functional.

Proper storage extends tool life and maintains safety characteristics. Store non-sparking tools separately from steel implements to prevent cross-contamination. Keep them in clean, dry conditions that minimize corrosion. Tool boxes or roll cabs with individual compartments prevent tools from striking each other during transport, reducing wear and damage.

Never attempt to harden or heat-treat non-sparking tools to increase their strength. Such treatments will destroy the non-sparking properties and create dangerous implements that appear safe but actually pose significant explosion risks. Similarly, grinding, filing, or machining to reshape worn tools can embed steel particles into the soft alloy surface. When tools become worn beyond effective use, they should be replaced rather than repaired.

Documentation of tool maintenance, inspection, and replacement supports both safety management and regulatory compliance. Tracking tool condition over time helps identify when particular applications are causing excessive wear, potentially indicating the need for higher-grade materials or alternative approaches. Maintenance records also demonstrate due diligence in safety equipment management during audits or investigations.

Building a Comprehensive Non-Sparking Tool Program

Individual tool selection represents just one component of effective hazardous area safety management. A comprehensive program ensures appropriate tools are available, properly maintained, and correctly used across all relevant operations.

Tool inventory planning should provide complete coverage of all tasks performed in classified areas. This requires analyzing job functions to identify every tool type needed, from common implements like wrenches and screwdrivers to specialized equipment for particular applications. Having the right tool readily available prevents the temptation to use makeshift alternatives or conventional steel tools that compromise safety.

Training ensures workers understand both the importance of non-sparking tools and their proper use. Personnel should know how to identify certified explosion-proof tools, understand why conventional tools are dangerous in their work environment, and recognize when tools need cleaning, maintenance, or replacement. Training should also cover the limitations of non-sparking tools—they prevent ignition from mechanical sparks, but they don't eliminate all ignition sources or substitute for other safety measures.

Clear policies and procedures establish expectations for tool use in hazardous areas. Rules should prohibit bringing personal tools or conventional implements into classified zones, require reporting of damaged safety tools, and define inspection and maintenance schedules. Enforcement of these policies must be consistent and visible, with management modeling correct behavior and addressing violations promptly.

Integration with broader safety programs ensures non-sparking tools function as part of layered protection strategies. Proper grounding and bonding prevent static electricity accumulation. Ventilation systems minimize explosive atmosphere formation. Hot work permits and gas monitoring provide additional safety layers. Non-sparking tools reduce one significant ignition source, but comprehensive safety requires addressing all potential hazards.

Discover Premium Non-Sparking Safety with Sparkless by The Bombay Tools

At The Bombay Tools, we understand that safety in hazardous environments cannot be compromised, which is why we manufacture a comprehensive range of premium non-sparking safety tools under our Sparkless brand. Our commitment to protecting workers in potentially explosive atmospheres drives everything we do, from material selection to manufacturing processes to quality control.

Our Sparkless non-sparking tool sets are engineered for the demanding requirements of oil and gas operations, chemical processing, mining, and other high-risk industries. Our tools are tested and conform to IS 4595 standard for non-sparking property, ensuring they meet rigorous Indian standards for safety performance. This certification provides confidence that every tool in our range has been verified to prevent spark generation in explosive atmospheres.

The Sparkless product line encompasses every tool type required for maintenance and operational tasks in classified areas. From non-sparking hammers and chisels to complete socket sets, from specialized striking tools to precision adjustable wrenches, our range provides comprehensive coverage for all applications. We manufacture both aluminum bronze and copper beryllium options, allowing you to select the material best suited to your specific operational requirements and budget constraints.

Beyond individual tools, we offer complete non-sparking tool sets that provide everything maintenance teams need in convenient, organized kits. These comprehensive sets ensure workers have immediate access to appropriate safety tools without needing to source individual implements from multiple suppliers. Our sets are designed based on real-world operational requirements, ensuring they contain the tools actually needed for typical tasks in hazardous environments.

Quality defines every aspect of our Sparkless manufacturing process. We use premium alloys sourced from reliable suppliers, employ precise machining and forging techniques that optimize tool performance, and implement rigorous inspection protocols that verify every tool meets our exacting standards. This attention to quality ensures that when you depend on Sparkless tools for safety, they'll perform exactly as required.

When you choose Sparkless non-sparking safety tools from The Bombay Tools, you're selecting more than just implements—you're investing in a comprehensive safety solution backed by manufacturing expertise, quality commitment, and understanding of hazardous environment challenges. We don't simply sell tools; we provide the peace of mind that comes from knowing your workers are protected by equipment that meets the highest safety standards.

Explore our complete range of Sparkless non-sparking tools at https://thebombaytools.com/product-categories/non-sparking-safety-tools and discover how The Bombay Tools can help you maintain the highest safety standards in your hazardous work environments. Don't compromise on safety—choose Sparkless for proven protection in explosive atmospheres. For more information about specific applications and material selection guidance, visit our blog at https://thebombaytools.com/blog-details/beryllium-copper-heavy-duty-non-sparking-tool-material or contact our technical team who can help you select the optimal tools for your unique operational requirements.