Industrial Drum Opener

Loading / Unloading Operations

Loading hazardous chemicals into drums and barrels to be transported to various plants across India is a common operation. Similarly unloading of these hazardous chemicals at the recipient site for further processing occurs daily.

The above two processes require well-designed protocols and procedures as any failures during this operation can have catastrophic results. We have seen that most industrial plants have formalized standard operating procedures when loading and unloading hazardous chemicals. Some of the common safety considerations are as per below:

- Taking preventive measures to avoid static electricity

- Ensure tightness of all valves

- Using hoses that are compatible with the product

- Ensuring correct pressure

- Checking tank capacity to avoid overfilling

- Wearing appropriate protective clothing, such as safety boots, gloves, safety glasses, etc.

The above is a small list of considerations when designing your SOP. After the product has been loaded into the drums both ends of the drum are capped and a seal is crimped onto the caps to prevent any tampering. At the receiving end, the seal is removed and the drum caps have to be opened using a drum opener.

Various plants employ different types of caps to seal the 2 ends of the drum. Unfortunately, this activity had received little attention and correct SOP was missing for the past few decades. However, this behavior is now changing and we are seeing many plants adopting best practices.

Those plants handling drums & barrels with hazardous equipment need to use non-sparking drum openers. As identified earlier, loading/unloading operations are fraught with challenges. Static electricity is not the only source of ignition. Steel tools used for this operation can also be a source of a spark as the tools may collide with each other or with the drum or some other components in the vicinity to create a spark. If there were any leaks or vapors formed these sparks can ignite the vapors creating a potentially catastrophic chain of reactions leading to loss of life and property.

Non-sparking drum openers and bung wrenches are available for the industry and these should be employed in any plant handling hazardous liquids. These tools are available in various designs so that they can be used on the different types of caps used on the drums. Many plants are using hacks or ‘juggad’ tools for this purpose. This practice needs to stop and operators should use tools designed for the task at hand. This ensures maximum safety.

OSHA - Occupational Safety and Health Administration of the United States clearly mandates non-sparking tools when opening or closing benzene containers.

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.1028AppA

This rule can be extrapolated to any hazardous liquid.

Our range of bung wrenches and drum openers is designed with all the different applications in various industries. We list is a few tools that are perfect for your plant.

Below are a few of our drum openers and bung wrenches that can work on a variety of plug caps:

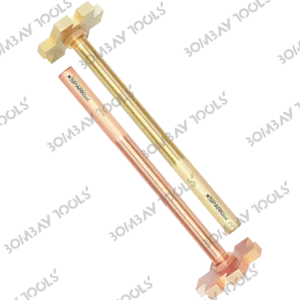

Circular Bung Wrench

This is the most popular tool as it is capable of opening 8 different types of caps and provides the best ergonomics for the user

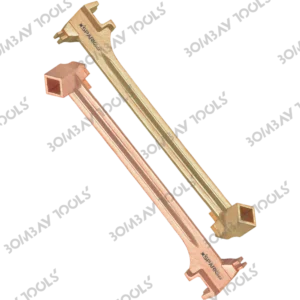

Bung Wrench

Figure 3 - Circular Bung Wrench for different plug caps of Drums

American Bung Wrench

This tool is popular for MS Barrels and Drums imported from the United States and is designed to fit the various drum caps employed in the US

Figure 2 - American Type Bung Wrench

This concentrates the pressure at the jaw teeth only and produces the maximum gripping force and aids ratcheting action.

If possible, always pull rather than push on the pipe wrench handle and maintain a proper stance with feet firm to hold the balance.

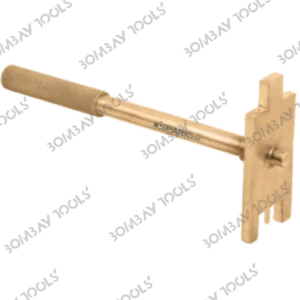

Standard Bung Wrench

Below is a standard bung wrench that is used in most FMCG, Breweries & Distilleries, Paint Industries, and many

Figure 4 - Standard Bung Wrench

When using a heavy-duty Pipe Wrench, maintain a gap between the back of the hook jaw and the pipe.

This concentrates the pressure at the jaw teeth only and produces the maximum gripping force and aids ratcheting action.

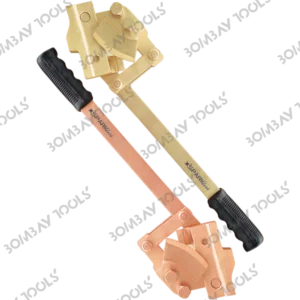

Drum Opener with Pin Hook

This Drum Opener serves in 2 ways - it helps with breaking the seal of the drum and the tool can then be used to open both the 70mm and 35mm plug-cap

Figure 5 - Drum Opener with a Pin Hook

Sparkless Non-Sparking cap seal removal tool provides a fast and safe way of removing cap seals. Simply hold the cap seals ear hole in the tool’s pin keeping the tool vertical. Then pull down the tool in a horizontal position, thereby tearing off the cap-seal smoothly

Drum Cutter

Besides the drum openers and bung wrenches our range of tools also includes a Drum Cutter. The Drum Cutter is useful for cutting open a 200 liter MS Drum head

Figure 6 - Drum Cutter for 200 liters MS Drum

Drum cutting pliers are designed for work involving the cutting of drum seals.

Drum Cap-Seal Crimping Tool

Loading operations usually require the drum plug cap to be crimped with a tamper-proof seal. We also have the following Crimping Tool for this purpose:

Figure 7 - Drum Plug Cap Seal Crimper

Drum Cap Sealer 2? and 3/4? - Manual model Non-Sparking

For Steel and Plastic Drums.Manufacturer and worldwide exporter of drum cap sealer/crimper of 2? and 3/4? size for use on 70mm and 35mm diameter cap seals on steel and plastic drums.

For more details, you can mail us at - info@bombaytools.in