Insulated Tools in the EV Industry

Introduction

The proliferation of electric cars, buses, and trucks will continue at a rapid pace as the world transitions away from fossil fuels. This swift growth, however, can create a knowledge gap, particularly outside the manufacturing sector. Consider the recovery, repair, and maintenance of electric vehicles (EVs). The current workforce, skilled in handling gasoline engines, may lack the knowledge and expertise to work on EVs. Furthermore, the increasing number of EVs on the road may outpace the development of these skills among non-OEM personnel.

This blog provides an introduction to the hazards involved for those working with EVs, particularly in the motor vehicle repair, roadside recovery, and emergency services industries.

Hazards in the EV Industry

Workers in the EV repair and recovery industry must be aware of additional hazards posed by electric vehicles. To work safely, they need enhanced skills, knowledge, and access to specialized insulated tools and equipment.

Key Hazards Include:

- High Voltage Systems: EVs operate at significantly higher voltages (up to 650V DC) compared to traditional vehicles (12/24V DC). Voltages above 110V DC can be fatal. In the EV industry, voltages between 60V and 1500V are classified as High Voltage (HV).

- Battery Risks: Batteries may release harmful chemicals if damaged and store substantial energy that can cause explosions if mishandled.

- Residual Energy: Components may retain dangerous voltages even when the vehicle is switched off.

- Unexpected Movement: Electric motors or the vehicle itself may move unexpectedly due to magnetic forces.

- Manual Handling Risks: Battery replacement can involve significant weight, posing physical risks.

- Silent Operation: EVs are silent, increasing the risk of unnoticed vehicle movement.

- Impact on Medical Devices: Electrical systems may interfere with devices such as pacemakers.

Identifying the Risks

EVs introduce new risks to workplaces involved in vehicle repair, roadside recovery, and related activities. These risks include:

- Presence of high voltage components and cables capable of delivering fatal electric shocks.

- Energy storage that can cause explosions or fires.

- Residual dangerous voltages even after the vehicle is switched off.

- Unexpected movement of the vehicle due to magnetic forces.

- Risks of explosive gases or harmful liquids being released if batteries are damaged.

- Increased manual handling risks during battery maintenance.

- Silent operation of EVs, making movement less detectable.

- Potential effects on medical devices such as pacemakers.

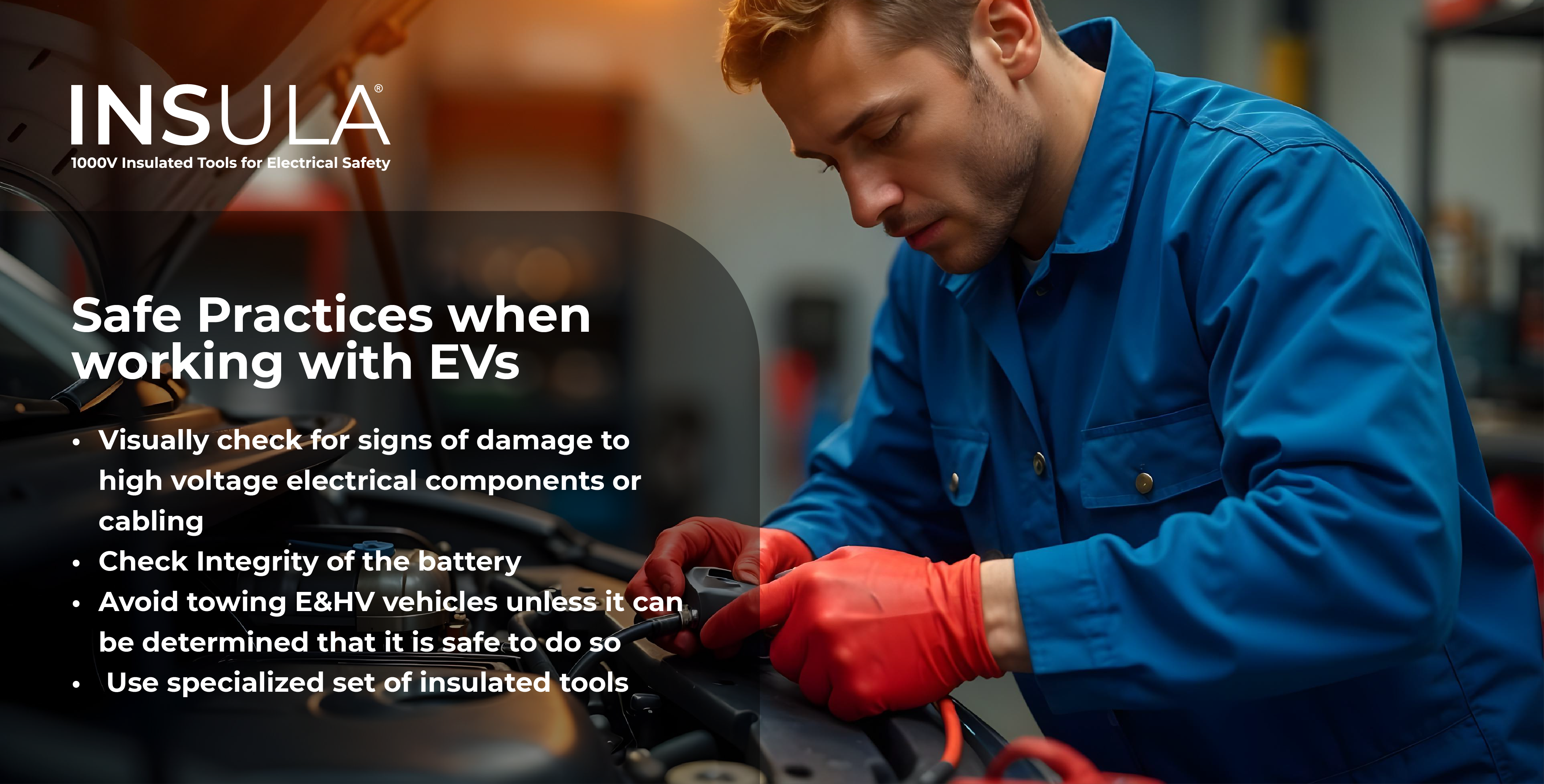

Overlays for Safe Practices

- Visually check for signs of damage to high voltage electrical components or cabling.

- Verify the integrity of the battery before working.

- Avoid towing EVs unless it is confirmed to be safe.

- Always use a specialized set of insulated tools.

Safe Practices When Working with EVs

The risks associated with EVs require specific skills and knowledge, depending on the activity being performed. Personnel can be categorized based on their roles:

1. First Responders and Emergency Services

First responders must visually inspect the EV for signs of damage to high voltage components or cabling (typically colored orange). They must also consider the integrity of the battery system and determine if it has been compromised. If the vehicle is damaged or faulty, and it is safe to do so, they should:

- Isolate the high voltage battery system using the vehicle’s isolation device.

- Remove the remote operation key to a safe distance.

- Disconnect the standard 12/24V battery to prevent accidental activation.

- Avoid towing EVs unless confirmed safe, as drive wheel movement can generate dangerous voltages.

- Use a specialized insulated tool kit for any necessary emergency work. This toolkit should include insulated pliers, screwdrivers, open spanners, sockets, knives, and mallets.

2. Maintenance and Repair

Before starting any work on an EV:

- Visually inspect for damage to high voltage cabling (colored orange) or components.

- Always isolate or disconnect the high voltage battery unless the task requires the vehicle to be energized. Follow the manufacturer’s instructions.

- Identify the location of high voltage cables before cutting, welding, or panel replacement. Take precautions to avoid damaging them.

A VDE 1000V Insulated Tool Kit should be maintained for repair work. This kit should include:

- Insulated open & ring spanners

- Insulated sockets and accessories

- Insulated pliers

- Insulated screwdrivers

- Insulated knives

- Insulated mallets

- A battery toolkit for specialized maintenance tasks.

3. Working on High Voltage Electrical Systems

When working on high voltage systems:

- Visually inspect for damage to high voltage components or cabling.

- Isolate and lock off the high voltage system to prevent accidental reactivation.

- Always test and confirm that no systems are energized before starting work.

- Be aware that even when isolated, batteries and components may retain high voltages. Use only suitable insulated tools and test equipment.

- Follow the manufacturer’s instructions for discharging stored energy.

If isolation is not possible (e.g., after collision damage), consult the manufacturer’s guidelines for additional safety measures. Live work on electrical systems should only occur when absolutely necessary, and only if it is both reasonable and safe. In such cases, implement robust precautions, including appropriate PPE.

A comprehensive insulated toolset for high voltage systems must include:

- Insulated sockets, torque wrenches, ratchets, and extensions

- A 50-piece interchangeable insulated screwdriver set for various tasks

- Insulated pliers and clamps for cable management

- Insulated open and ring spanners for handling bolts and nuts