Non-sparking & Insulated tools in Breweries & Sugar Industry

A study on the potential hazards in the manufacturing handling/storage of sugar/distillery plant section was done by Mr. Vinod Sahasrabude. This study reveals that the Alcohol Production area is hazardous due to the possibility of alcohol vapour release. It further recommends hazop study for production and storage of Alcohol. In particular special attention should be paid in design to ensure intrinsically safe operations.

Risk of Fire and Explosion

Distillery Plant section

In the Distillery Plant section 7.6.1.1 categorically mentions:

Keeping away from heat, sparks and open flame, care will be taken for avoidance of spillage, skin and eye contact, well ventilation, Use of approved respirator if concentration of alcohol in air is above acceptable level will be promoted

To ensure no sparks it is very critical to use non-sparking hand tools in the Distillery Plant. In fact many sugar and distilleries maintain a non-sparking toolkit with commonly used tools for performing maintenance and operations in this area

Sulphur Storage

Section 7.6.2.3 identifies Sulphur dust as a potential hazard for dust explosion. One of the conditions for dust explosion in this area has been identified as:

Presence of source of ignition

Sulphur dust has a very low ignition temperature of 190 °C. Further Sulphur burns to produce SO2 (Sulphur dioxide) gas which is extremely irritating and toxic. This create a double hazard as Sulphur dust not only has a risk of igniting and causing other accidents but the SO2 fumes can also prove fatal for personnel operating in its presence.

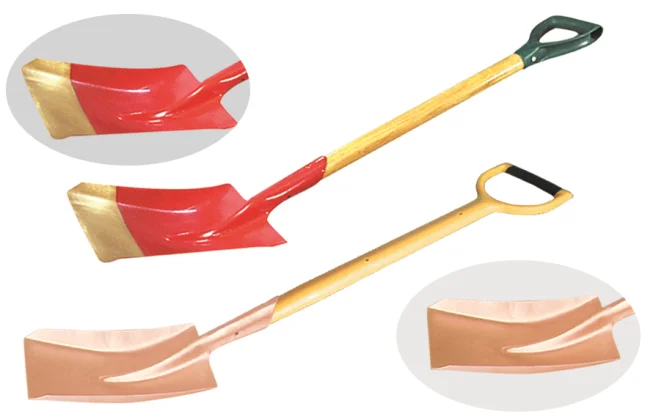

A mitigation measure identified by the author for the above is use of a non-sparking scoop and non-sparking shovel in this area to avoid any stray sparks

|  |

Non-Sparking Scoop | Non-Sparking Shovel |

Further if any other hand tools are required in this area it should be non-sparking to preclude any sources of ignition as 7.6.2.3.1.e

.webp)

Non-Sparking Toolkit for Hazardous Areas

Risk Of Electrocution

Another type of hazard identified in this study is electricity hazard. To prevent this section 7.5.1.1.A states the following:

Use of approved insulated tools, rubber mats, shockproof gloves and boots, tester, fuse tongs, discharge rod, safety belt, hand lamp, wooden or insulated ladder and not wearing metal ring and chain

The emphasis in the above section is on “approved” insulated tools. While many hand tools have rubber grip on it but the same cannot be classified as insulated tools because they are not tested or verified. Insulated tools should be tested and certified to the IEC 60900 standard and only then can the insulation on the tools said to be approved. We have a wide range of insulated tools that can be procured as per your requirement. We have attached below an insulated toolkits that has some of the most commonly used tools by your technician.

31pc Insulated Toolkit

31pc Insulated Toolkit