Ultimate Tensile Strength - Best Indicator of Material Strength

Introduction

The recent launch of Copper Titanium non-sparking tools has created confusion within users of hand tools in hazardous locations. The claim made here is that Copper Titanium is superior to Beryllium Copper since it has the same strength but without the hazardous element Beryllium in it. Both these claims are nothing more than marketing shenanigans. Our experience supplying Copper Titanium from 2017 to 2020 has proven both. Firstly, there is no comprehensive study or directive anywhere globally that says Beryllium Copper in solid form is a health hazard. We have written about this extensively in our prev blog. Secondly, Copper Titanium does not have strength that can match Aluminium Bronze let alone Beryllium Copper as you will see below.

Properties of BeCu

Beryllium Copper has the following chemical and mechanical properties:

| Material | Beryllium-Copper |

| Composition | Be: 1.8 – 2.3 % Co + Ni: Over 0.2 % Co + Ni + Fe: below 1.2 % Balance- Copper |

| Hardness | 30 ~ 41 HRC |

| Ultimate Tensile Strength | 1050N/mm2 ~ 1326 N/mm2 |

While hardness and composition (in the above table) can easily be ascertained on a finished Beryllium Copper tool, most manufacturers will inform you that the UTS need to be done on a specially prepared specimen. This raises the question about the strength of the finished tool itself. Is this claim of strength similar to claims made by auto companies about fuel efficiency under pristine lab conditions? We believe this is a valid concern from an end users perspective that needs the best (high strength) tools in their plants for their operation and maintenance. This blog is our attempt to demystify the issue surrounding the strength we can expect from an actual tool when a UTS test is performed.

Ultimate Tensile Strength

Tensile strength testing usually reveals 3 different metrics namely Yield Strength, Young’s modulus and Ultimate Tensile Strength. Our focus for hand tools is the ultimate tensile strength only. The UTS value gives us sufficient confidence about the actual tool strength when it will be used.

To measure UTS we need to divide highest load experienced by the specimen before rupture by the original cross section of the test specimen. Simply:

UTS = Breaking Force / Cross Sectional Area

Tool Selection

Most hand tool size and shape do not lend itself very well to this testing as cross sectional area needs to be uniform across the length of the specimen that is under load. We have found that screwdriver blades are cylindrical and lend themselves well for such testing as its dia is the same across the blade length. Further, it does not require any machining and testing can be done to get a ballpark figure on the strength of the tool

Actual Testing

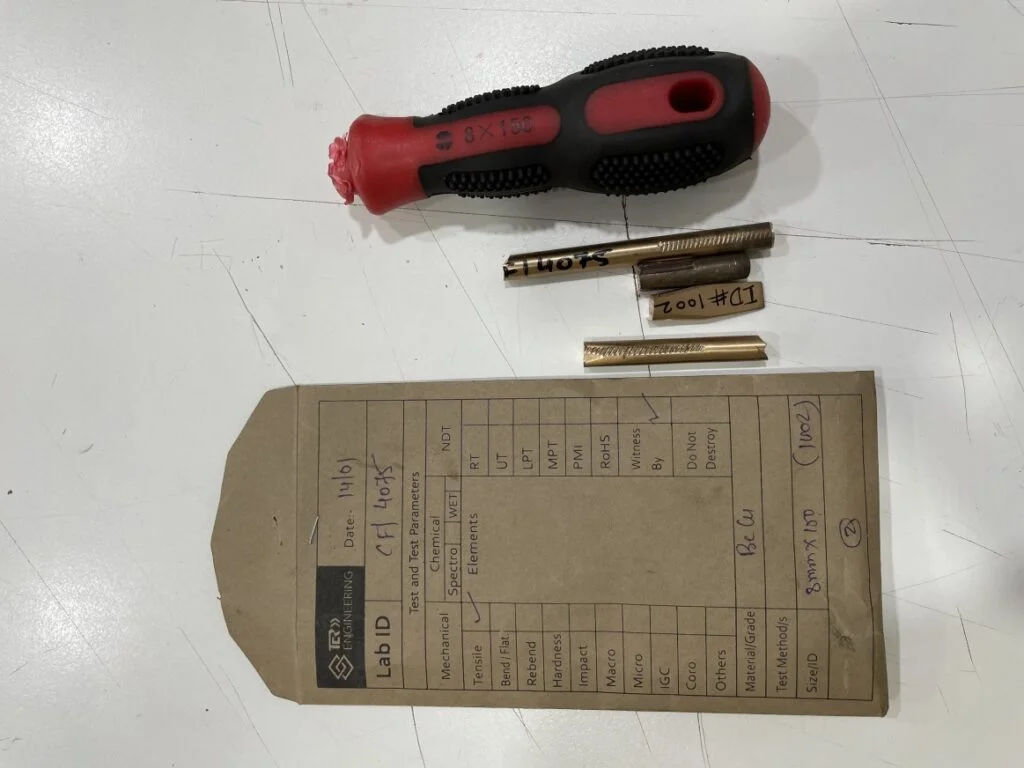

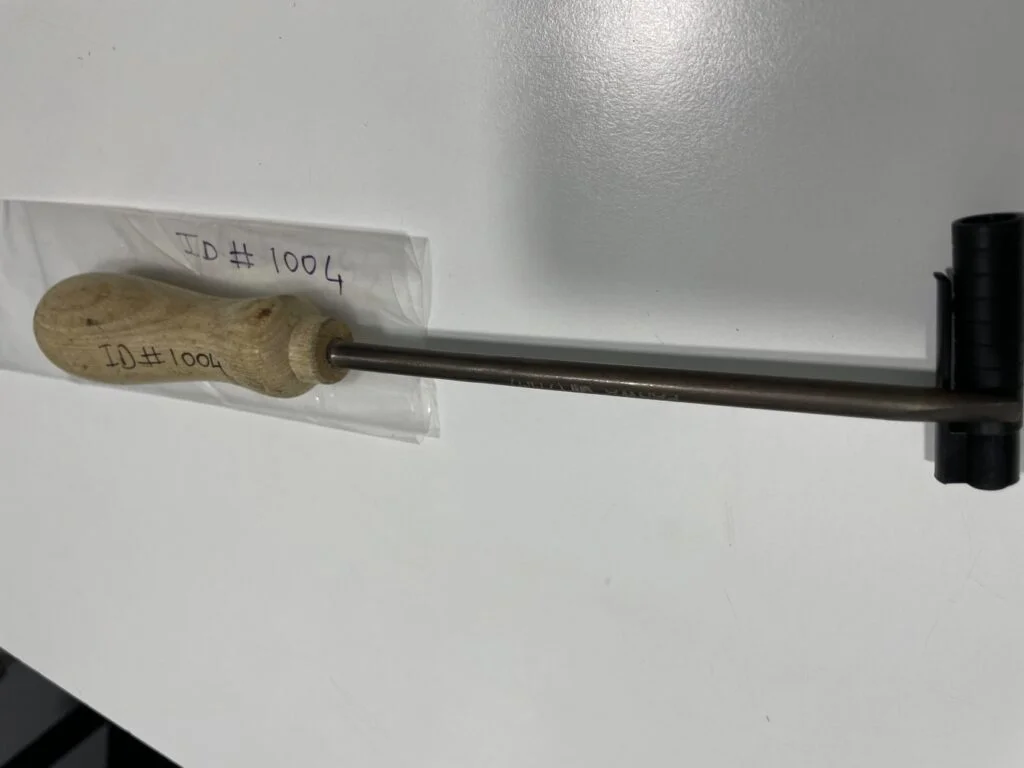

Below we have selected a Beryllium Copper Screwdriver of ?8*150mm long. The handle of the tool is removed and the 2 ends of the blades are cut to get one uniform cylindrical specimen that can be load tested.

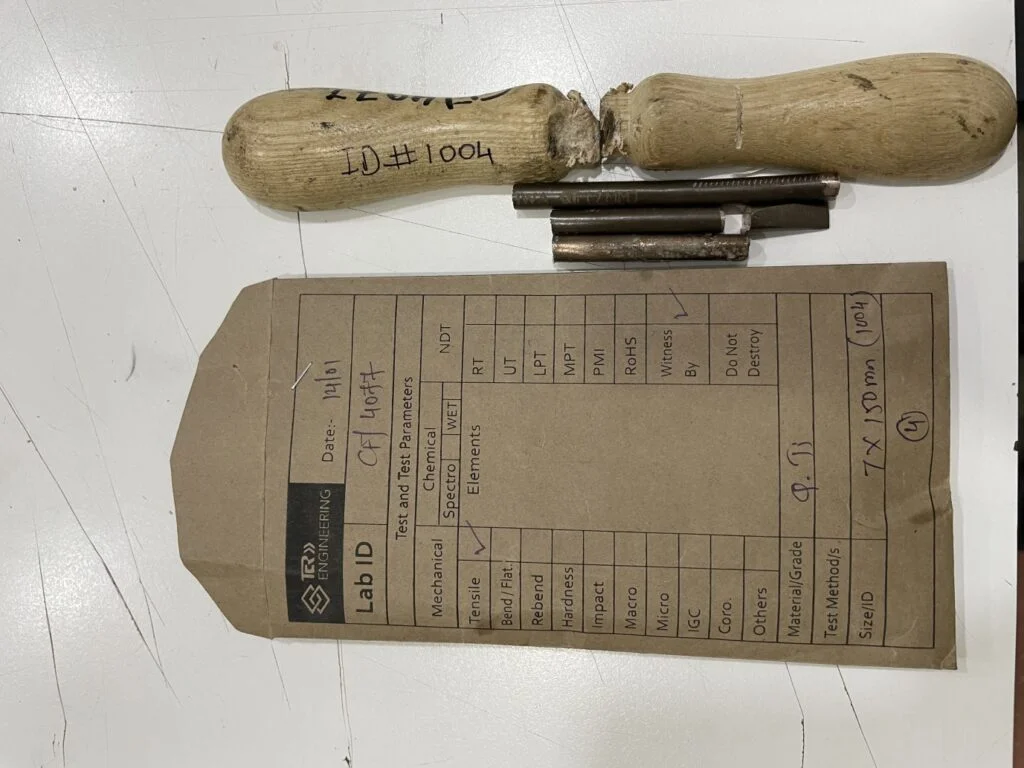

Figure 2 shows the tool samples after the test has been completed. The broken bit of the tool represents the point at which UTS was recorded (Figure 3).

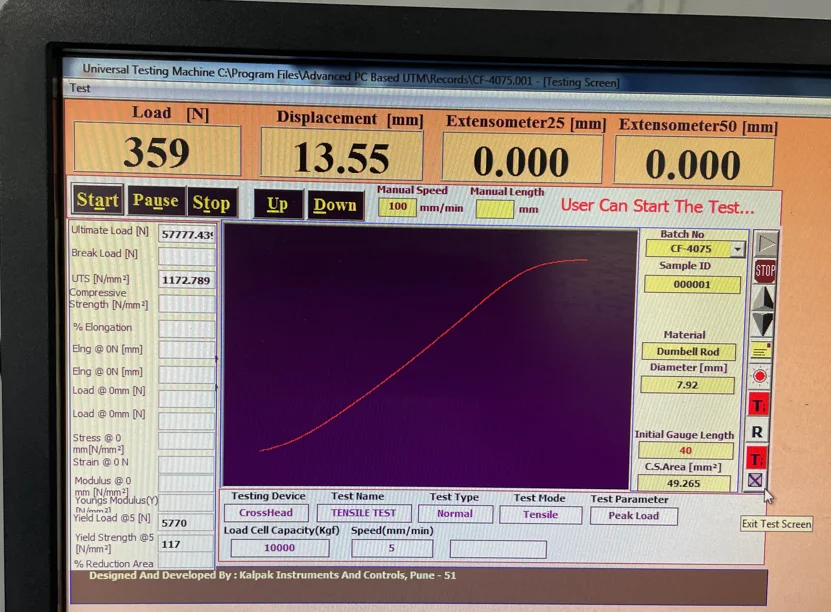

Figure 3 - Result as observed on the PC

Figure 3 - Result as observed on the PCUTS Results and What It Means

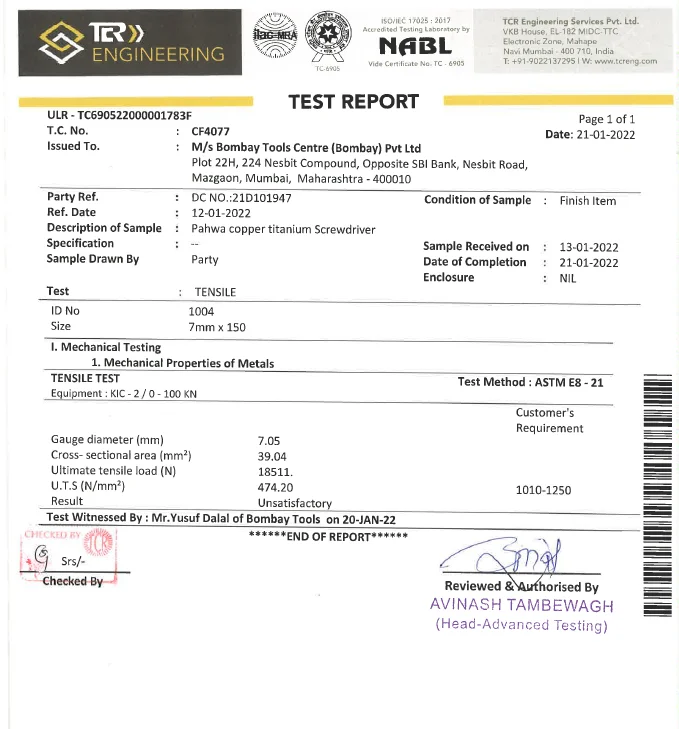

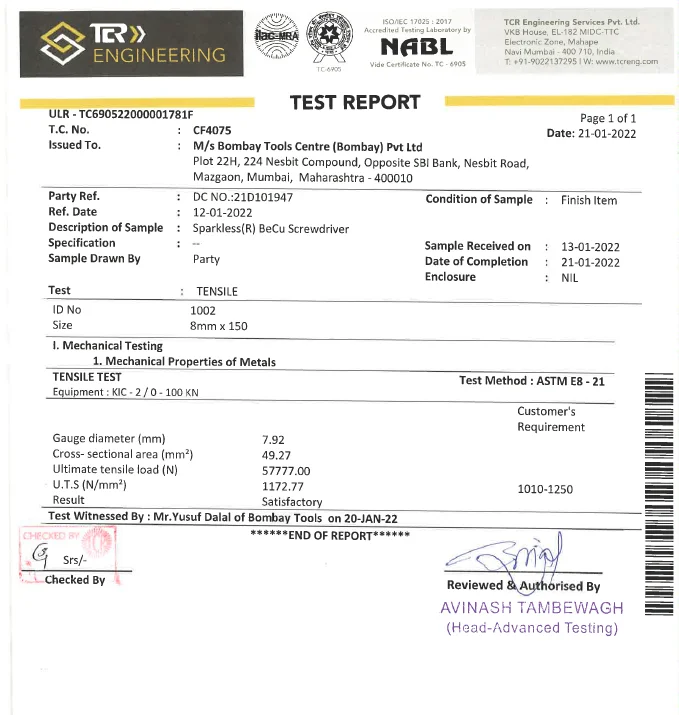

Below is a screenshot of the NABL test report:

This screwdriver has exhibited an ultimate tensile strength of 1172.77 N/mm2 (MPa). This value is consistent with the range advertised as property of Beryllium Copper. This gives users of our Sparkless ® Beryllium Copper tools the confidence that the tool is of excellent strength and will perform for its intended application in their plant while providing safety against accidental sparks.

Similar tests were done with 2 additional Beryllium Copper screwdrivers. One was the same size i.e. ?8*150mm and the other was Philips Screwdriver of size 75mm long. They have exhibited UTS of 1199.61 N/mm2 and 1192.28 N/mm2 respectively.

UTS of a Copper Titanium Tool

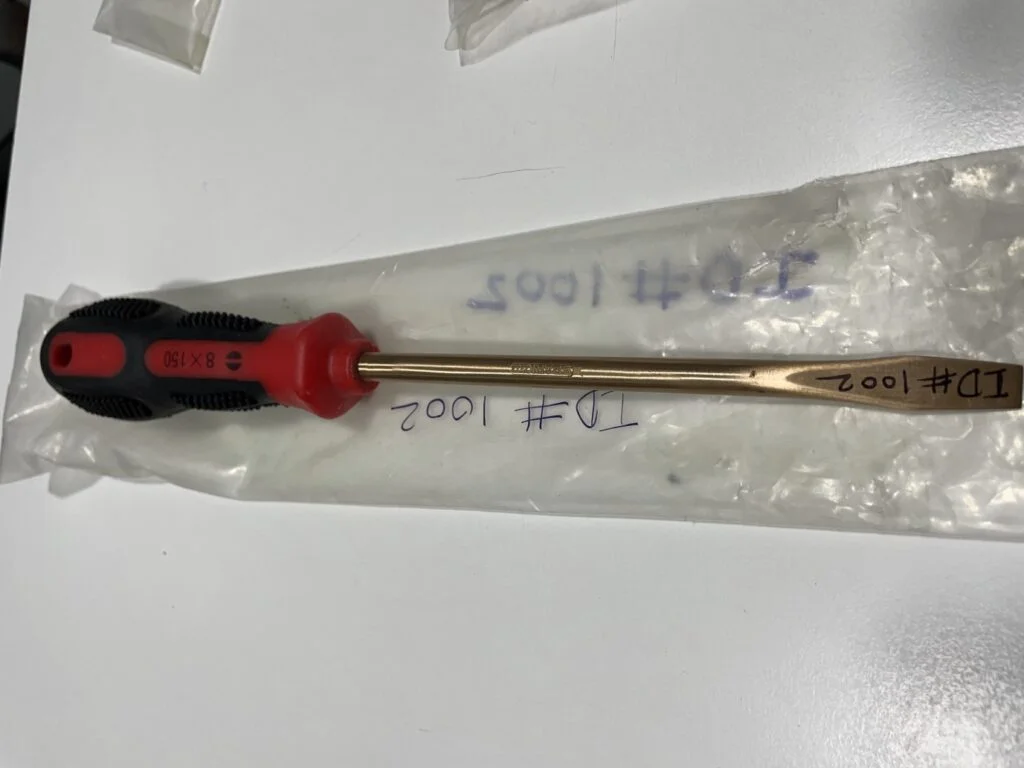

In the interest of fair comparison we decided to perform a similar test with a Copper Titanium Screwdriver. Below is a picture of a Copper Titanium screwdriver. We have selected which is of the same size i.e. ?8*150mm long.

Snapshot of the tool after the test is complete

Below is a screenshot of the NABL test report: