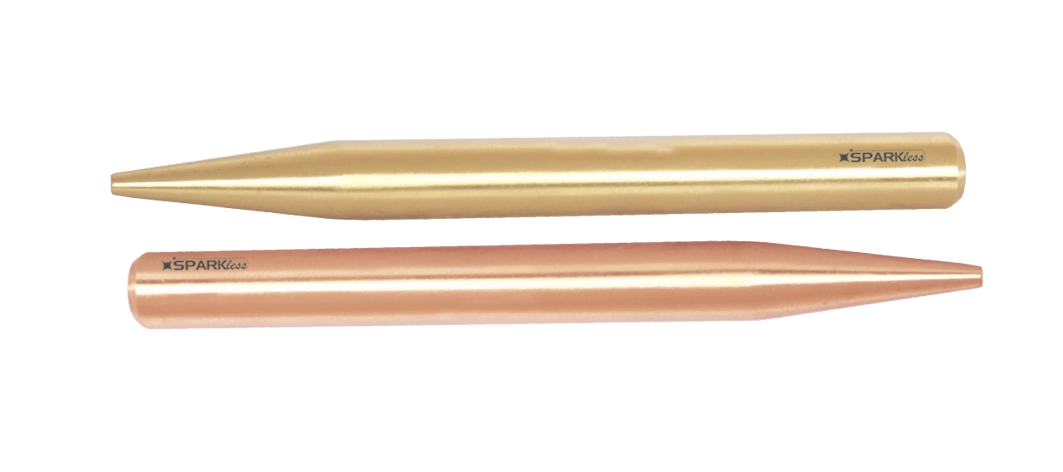

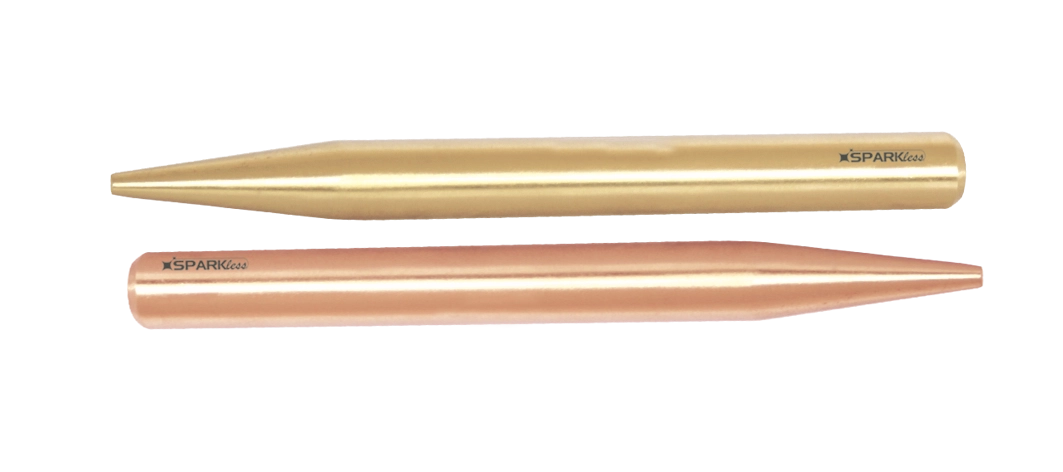

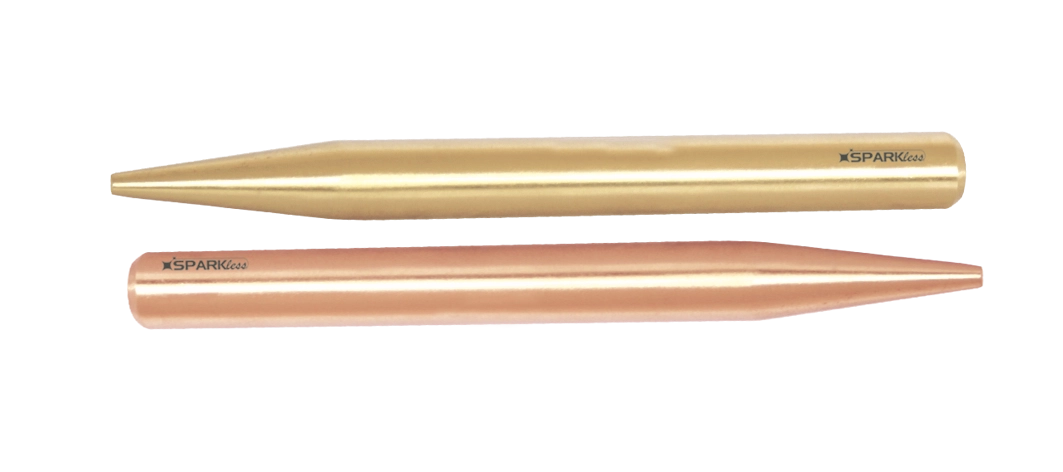

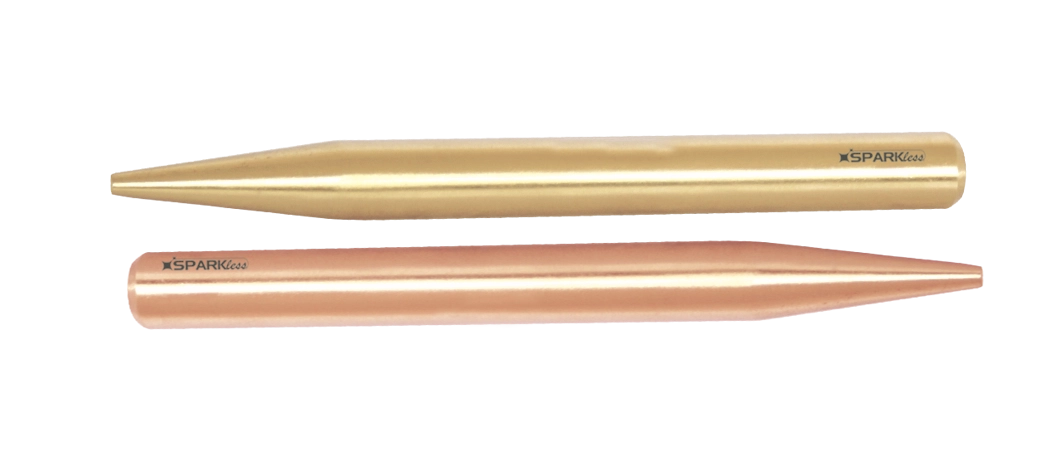

Non-Sparking AlBr Punch 8 mm

₹ 797.55 + 18% GST

-

non-sparking-albr-punch-8-mm-svcc-1008a

Our Non-Sparking Punch is the best alternative to regular tools and finds application in potentially explosive environments.

Non-Sparking Tools are mandatory in any environment where an ignition source can result in a fire or explosion.

Our tools are tested and comply with IS 4595 standards for non-sparking properties.

| Item Name | P/N | f mm | f1 mm | L mm |

| Punch | SVCC-1002 | 5 | 11 | 150 |

| Punch | SVCC-1004 | 6 | 12 | 150 |

| Punch | SVCC-1006 | 7 | 13 | 150 |

| Punch | SVCC-1008 | 8 | 14 | 150 |

Mechanical Properties

We offer 2 kinds of materials for non-sparking tools,

Copper-Beryllium alloy (Be-Cu) and Aluminium-Bronze (Al-Br) alloy:

| COPPER-BERYLLIUM ALLOY | ALUMINIUM-BRONZE ALLOY | ||

| Composition | Be: 1.8%-2% Ni+Co: 0.2%-1.2% Others: <0.5% Rest: Cu | Composition | Al: 10%-12% Ni: 4 % – 6 % Fe+Mn: <5.8 % Others: <0.5% Rest: Cu |

| Hardness | 283-365 Brinell | Hardness | 229-291 Brinell |

| Tensile Strength | ~1250 N/mm2 | Tensile Strength | ~800 N/mm2 |

Proper component alignment prevents stress concentrations, leaks, and premature failures in piping and pressure systems. Non-sparking punches allow precise positioning work near flammable process streams.

Fabrication shops in refineries, maintenance workshops in chemical plants, shipyard operations, and mining equipment repair facilities use non-sparking punches daily for assembly and repair work.

Guest May 04, 2026

Useful tool for refinery and gas plant maintenance.

Guest September 19, 2024

Using this tool regularly in oil and gas facilities.

Guest February 10, 2025

Safe and dependable tool for routine maintenance work.