Understanding What are Insulated Pliers: A Complete Guide

What are insulated pliers used for?

Insulated pliers are used to safely grip and manipulate conductive materials or wires, protecting the user from electric shocks. The insulating material on the handles prevents electricity from passing through the tool to the handler, making them essential for electrical work and working on live circuits.

What are insulated handle pliers?

Insulated handle pliers are tools designed with insulating material covering the handles to protect users from electric shocks when working with live wires. These pliers are essential for electrical work, as they prevent accidental contact with live circuits, ensuring safety during repairs and installations.

Key Highlights

- With their insulation on the handles, pliers keep you safe from electric shock.

- They're good for working with up to 1000V AC and even 1500V DC.

- Known for lasting a long time and keeping electricity at bay, these pliers are pretty reliable.

- For safety, the voltage range they can handle is usually marked right on the handles.

- Keeping you from getting hurt by blocking electricity is a key thing about insulated pliers.

- The highest voltage they can safely deal with depends on their dielectric breakdown voltage.

Introduction

Insulated pliers are super handy Insulated tools that help keep you safe from electric shock while working with equipment that's powered on. These tools come with a special insulated handle to protect you against big shocks, making sure you stay safe. With materials made for insulation and handles designed for comfort, these pliers last long and can be relied on for all sorts of electrical jobs. It's really important for anyone doing electrical work to know how valuable these tools are in avoiding injuries and keeping things running smoothly.

The Essentials of Insulated Pliers

Insulated pliers are essential hand tools for electricians, designed to keep them safe from electrical shock when they're fixing or working on live equipment. With an insulated handle, these pliers help shield the user from high voltages. The handles are often made with a type of insulation material known as comfort grips, which not only makes them safer but also more durable. By meeting international standards like DIN EN and ASTM, these pliers ensure that electricians can hold onto things securely without getting hurt, lowering the risk of injury during electrical work.

Defining Insulated Pliers and Their Importance

Insulated pliers are tools you can hold in your hand, made to keep you safe from electric shock when you're working with electricity. With insulation material covering the metal parts, these pliers help protect you while touching electrical contacts. This key feature is super important for keeping people safe, especially where there's a lot of voltage involved. For folks like electricians or anyone dealing with live equipment, using these pliers lowers the chance of getting hurt or having an accident. So, they're pretty much a must-have for any kind of electrical work.

Core Materials Used in Manufacturing Insulated Pliers

Insulated pliers are made with a mix of special materials to work well and keep you safe. With insulation like rubber or plastic, they help protect against electric shock. On top of that, the metal parts are crafted from tough stuff like chrome to make sure they last long and can handle different types of jobs. By picking these materials carefully, the makers ensure these pliers stick to global standards and offer solid protection when doing electrical work.

Further, a special handle is designed for these pliers that prevent the hand from accidentally slipping and coming in contact with the metal portion of the jaw

There are different kinds of insulated pliers made for certain jobs. With insulated needle nose pliers, you can work accurately in tight spots. Insulated combination pliers are great because they let you cut and grip things, making them really versatile. When it comes to doing electrical work near live equipment, there are special insulated pliers that keep you safe from electric shock. Each kind has its own use, giving people choices based on what they need to do while reducing the danger of getting shocked.

Safety Standards and Certifications for Insulated Pliers

Knowing how safe your insulated pliers are is key to avoiding electric shocks. For starters, the VDE standard plays a big role in making sure these tools meet international safety rules. On top of that, other important standards like ASTM and IEC help check if the pliers' quality and insulation are up to scratch. By sticking to these certifications, folks can lower their chances of getting hurt when dealing with live wires and bare metal parts. Aiming for such safety measures ensures that insulated pliers do what they're supposed to in all sorts of electrical jobs, keeping you safe from electric shock and reducing the risk of injury around the exposed metal.

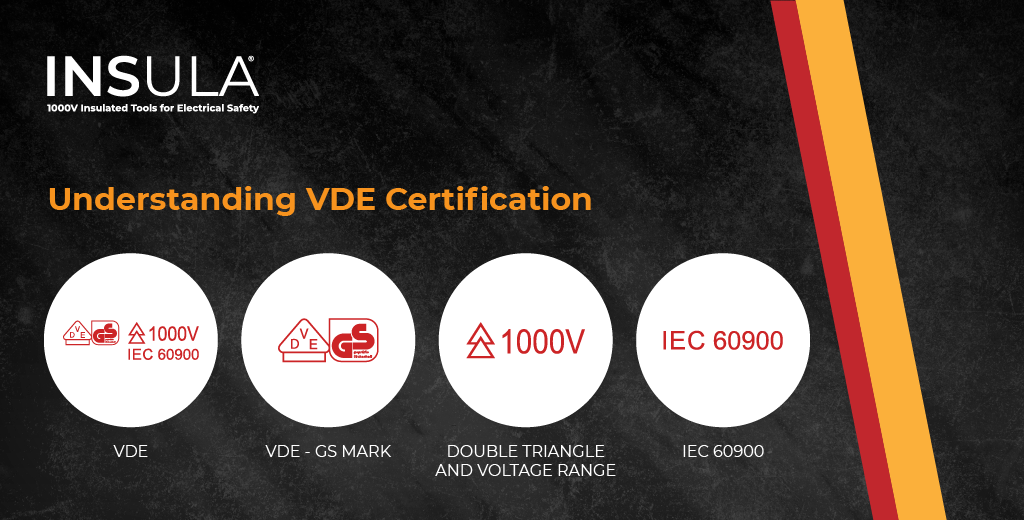

Understanding VDE Certification

The VDE certification, given by the Verband Deutscher Elektrotechniker, makes sure that insulated pliers are safe for electrical work. This approval shows that these tools can protect you from electric shocks. It details the voltage range they're good for, what kind of insulation materials are used in them, and how they keep you safe from touching live equipment directly. With this certification, handle pliers meet DIN EN standards which lowers the chance of getting hurt. By following VDE rules, you feel safer working around electrical contacts. There are other certifications too like ASTM and IEC or those by well-known brands such as Knipex and Wiha that also show a tool meets international safety guidelines.

Other Relevant Safety Standards

When picking out pliers that are insulated, it's really important to make sure they follow safety rules set by big names like ASTM, IEC, and DIN EN. These aren't just random letters; they're guidelines from around the world that say your tools are safe for working with electricity. On top of this, if you see a tool from well-known brands like Knipex or Wiha, you can be pretty confident it's good quality because these companies stick closely to those industry standards. Choosing tools that pass these strict checks is key because it lowers the chance of getting an electrical shock or hurt while working on live equipment.

Using Insulated Pliers Effectively

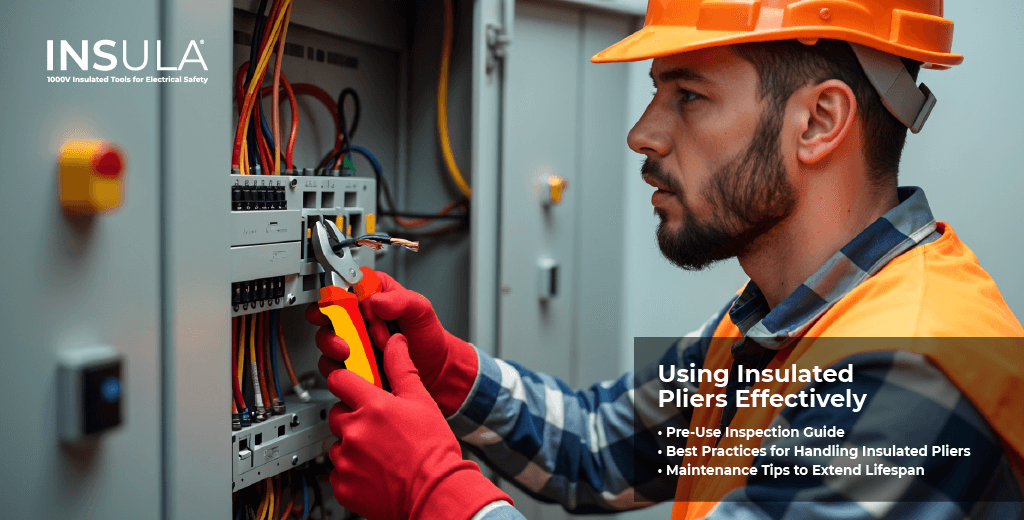

Before you start using insulated pliers, it's important to check them over to make sure the insulation hasn't been damaged. When working with electricity, pick the right kind of pliers that match the voltage you're dealing with; this helps lower your chances of getting an electrical shock. It's a good idea to use pliers with comfort grip handles if you'll be holding onto them for a while because they're easier on your hands. To keep your pliers in top shape for longer, follow some basic care tips like regularly looking out for any wear and tear on the insulation material and replacing them as soon as there’s damage spotted. Handling insulated pliers correctly is key when doing electrical work safely.

Pre-Use Inspection Guide

Before you start working with insulated pliers, it's important to give them a good once-over. Look closely at the insulation material to make sure there aren't any cracks or signs of wear that might let electricity through. With the handles, check they're firmly attached and not damaged in any way. Make sure the pliers are clean and don't have anything on them that could unexpectedly conduct electricity. It's also crucial to ensure these pliers can handle the voltage range you'll be dealing with in your task. By following these steps for checking your tools before use, you help keep yourself safe from electric shock and make sure everything goes smoothly.

Best Practices for Handling Insulated Pliers

When you're using pliers with insulation, make sure they're always in tip-top shape. Before you use them each time, look closely for any signs of damage or wear and tear on the insulation. It's really important to keep your pliers clean and dry because if the insulation gets compromised, it could be bad news. Also, when putting them away, find a spot that's dry and doesn't get too hot or cold. From time to time, give the handles a once-over to check for any damage so you can hold onto them securely without risking an accident.

Maintenance Tips to Extend Lifespan

To keep your insulated pliers working well and safe from electrical shock, it's important to look after them regularly. Here are a few ways you can make sure they last longer:

- After using your pliers, always clean them to get rid of any dirt or bits that might mess with how they work.

- With the handles, check for any damage like cracks or insulation coming apart. If there's any harm spotted, it’s best to get new ones right away so you don't risk getting shocked.

- Don’t use your insulated pliers on anything that has more voltage than what they're meant for. Doing this could ruin their insulation and be dangerous.

- Keep your insulated pliers in a place that’s dry and tidy; this helps stop rust or other damage to the insulation material.

- You might also want to use protective covers when you’re not using your pliers just to add an extra layer of safety.

Sticking with these maintenance steps will help ensure that your pliers stay in top shape and continue providing good electrical insulation while you work.

Common Applications of Insulated Pliers

Insulated pliers are super handy for all sorts of electrical work. Here's where they really come into play:

- When it comes to setting up or fixing things that run on electricity, insulated pliers are a go-to tool. They're great for dealing with wires, breakers, and those bits called electrical contacts. The insulation on these pliers keeps you safe from shocks when you're working around power that's turned on.

- In the world of cars and their electric parts, insulated pliers take center stage too. Whether it’s mending a wire that's not doing its job or putting in new stuff under the hood, these tools make sure you don't get zapped by keeping the electricity at bay while you tinker with your vehicle’s electric system.

- For folks setting up telecom services like phone lines or internet cables, insulated pliers come in real handy as well. They help manage cables and ensure whoever is installing them doesn’t get an unwanted shock from live connections in telecommunication gear.

Electrical Installation and Repairs

Insulated pliers are super important when it comes to setting up or fixing electrical stuff. Whether you're putting in wires for a new place or sorting out issues with electricity, these pliers keep you safe from getting an electric shock because they stop the electricity from reaching you.

For tasks like wiring, insulated pliers come in really handy. With them, electricians can work on live circuits without worrying about getting shocked. They help get a good grip on the wires and make sure you don't accidentally touch something that's live.

When dealing with breakers, these pliers are also useful. They let electricians safely install and look after breakers to ensure everything works as it should.

Another key job for insulated pliers is when working with electrical contacts. These tools allow workers to handle parts of live equipment without risking an electrical shock, which is crucial for safety.

All in all, having insulated plies around is essential if your job involves installing or repairing anything related to electricity since they provide protection through their insulation capabilities ensuring everyone stays safe from dangerous shocks while handling wiring, breakers, and other components like electrical contacts.

Automotive Electrical Systems

In the world of cars and their electric parts, there's a tool called insulated pliers that gets used a lot. These tools are super important for figuring out electrical problems and fixing connections that aren't working right. They make sure everything is safe and works like it should.

With car electrical systems using power from 12V all the way up to 48V or even more, having pliers with good insulation means you can work on these without worrying too much about getting zapped by electricity.

When someone needs to fix something in these systems, they grab them for jobs like cutting wires, peeling off wire covers, and putting connectors together just right. Doing this kind of work needs steady hands and tools that keep you safe; insulated pliers do both things well.

These special kinds of pliers don’t just stop people from getting an electric shock; they also help avoid any sparks that might mess up other delicate parts inside your car. By using them, anyone doing electrical work makes sure it’s done safely but still efficiently.

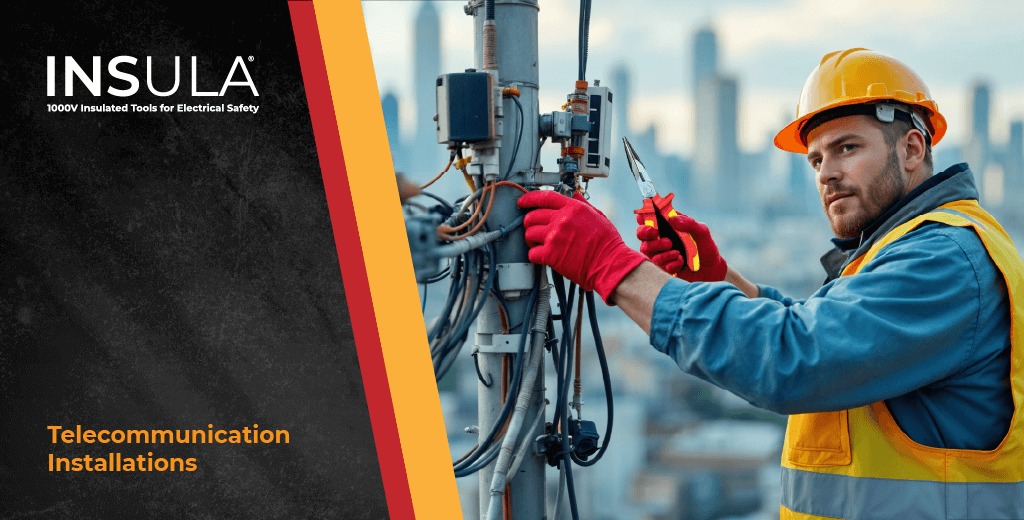

Telecommunication Installations

In the world of setting up telecommunication systems, where handling wires and keeping cables in order is a big deal, having insulated pliers is super important. These tools come with electrical insulation which means they keep people safe when they're working around electricity that's live.

For tasks like connecting wires, taking off the insulation, and putting connectors together in these setups, you really need something precise but also safe. That's where insulated pliers come into play.

When dealing with sensitive gadgets like routers or phones during these installations, it’s crucial to avoid any electric mishaps. Insulated pliers help make sure both the person doing the work and their equipment stay out of harm's way from electrical issues.

No matter if someone is putting in new gear for communication or figuring out problems with what’s already there, insulated pliers are key for those who do this kind of work. They make installing telecommunications stuff not only safer but smoother too so everyone can stay connected without a hitch.

Conclusion

Getting to know about insulated pliers is really important for keeping safe when working with electricity in different fields. This includes jobs like setting up electrical systems, fixing cars, or dealing with phone and internet connections. Using these pliers the right way helps stop accidents and makes sure things run smoothly. If you take good care of them and make sure they meet safety rules, such as having VDE certification, they'll last longer. Checking them regularly and using them correctly matters a lot too. When it's time to get some insulated pliers for your work, go for brands that are well-known for their quality. Always put safety first when picking out tools.

Frequently Asked Questions

How do I verify my pliers are properly insulated?

To make sure your pliers are safe to use, you should take a good look at them and keep an eye out for these things:

- With the insulated handle, it should have a coating made of rubber or plastic that stops electricity from passing through.

- On the pliers, look for marks that show they meet VDE certification or other safety standards.

- Look over the pliers carefully for any damage or signs of wear on the material used to insulate them.

- It's important to check that your pliers can handle the voltage range needed for your electrical jobs.

By regularly checking and sticking to safety guidelines, you'll help ensure your insulated pliers give you proper protection against electric shocks during work.

Can insulated pliers prevent all types of electric shocks?

Even though pliers with insulation help keep you safe from getting shocked, they can't stop every kind of electric shock. These kinds of pliers are made to be safe up to certain amounts of electricity and work best within those limits. If you're dealing with really strong electricity or dangerous situations, you'll need more than just these pliers to stay safe.

When it comes to working with electricity, sticking to safety rules is key, no matter what tools you're using. Pliers that have this special coating are super important for electrical jobs but remember, they're just one part of staying safe. You've got to use them along with other ways of protecting yourself so the risk of getting an electric shock is as low as possible.

How often should insulated pliers be replaced?

How often you need to swap out your insulated pliers can depend on a few things like how good the pliers are, how much you use them, and what shape the insulation material is in. It's a smart idea to check them now and then for any wear or damage signs. If the insulation isn't looking right or if the pliers seem worn out, it's time to get new ones straight away to keep yourself safe. Also, sticking to what the maker of your pliers suggests and keeping up with safety rules is key when figuring out how long your insulated pliers will last.

Are there any specific brands known for their quality in insulated pliers?

When it comes to finding top-notch insulated pliers, a few names stand out. Insula pliers, Klein Tools, Knipex, and Wiha are among the big players known for their dedication to crafting quality and safe tools. These brands have earned their stripes in the tool world by consistently providing professionals across different fields with reliable and long-lasting pliers. If you're on the hunt for insulated pliers, going with one of these reputable brands is a smart move because they've proven time and again that they can deliver the goods.

How to know if pliers are insulated?

Insulated pliers are typically marked with a symbol or label indicating that they are insulated. Look for markings such as "1000V" or the international symbol for insulation, which is a square inside a square. Additionally, insulated pliers usually have colored handles, with red, yellow, or orange being common colors for insulation. Always make sure to check the manufacturer's specifications or consult with a professional if you are unsure about the insulation level of your pliers.

What is the difference between insulated and normal pliers?

Insulated pliers are specifically designed to protect users from electrical currents, making them safe to use when working with live wires or circuits. They have insulated handles that help prevent electric shocks and ensure user safety. On the other hand, normal pliers do not have this insulation and should not be used when working with electricity, as they do not provide protection against electrical hazards. It is crucial to use insulated tools when working on electrical projects to reduce

Can you use pliers to crimp wires?

Yes, pliers can be used to crimp wires. However, it is important to use the right type of pliers for crimping to ensure a secure connection. There are specific crimping pliers designed for this purpose, such as wire crimping pliers or crimping tools. Using the correct tool will help create a reliable and safe connection when working with wires.

An insulated tool is a tool that has been designed with a protective covering or material to prevent electric shock when working on electrical systems. These tools are specifically made to provide a safe working environment for individuals who may come in contact with live electrical components. The insulation on the tool acts as a barrier between the user and any potential electric current, reducing the risk of injury or electrocution. It is important to use insulated tools whenever working on or near electrical systems to ensure personal safety and prevent accidents.

What is the difference between pliers and pincers?

Pliers and pincers are both types of hand tools used for gripping and cutting, but they have some key differences. Pliers typically have two jaws that are used to grip, turn, or bend objects, while pincers have pointed, often curved jaws that are used for cutting and pulling nails or other materials. In essence, pliers are versatile tools for gripping and manipulating objects, while pincers are more specialized for cutting and pulling tasks.