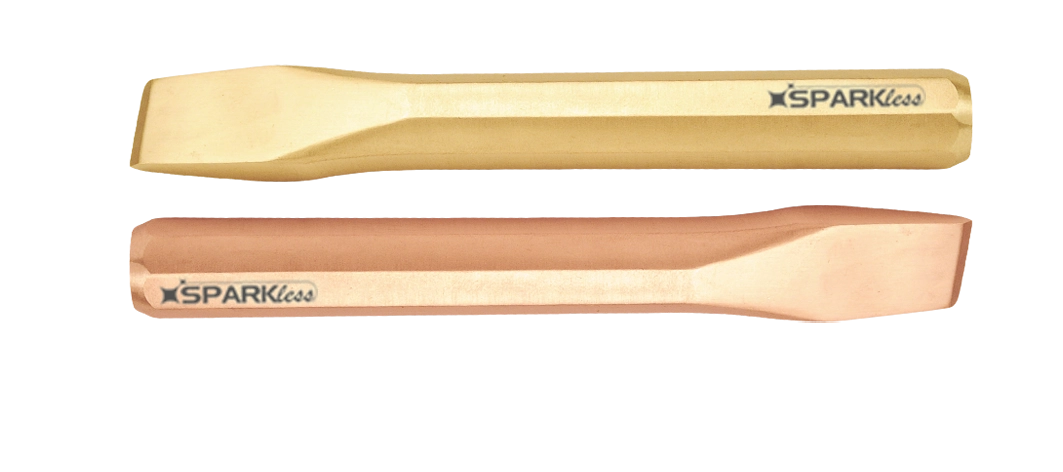

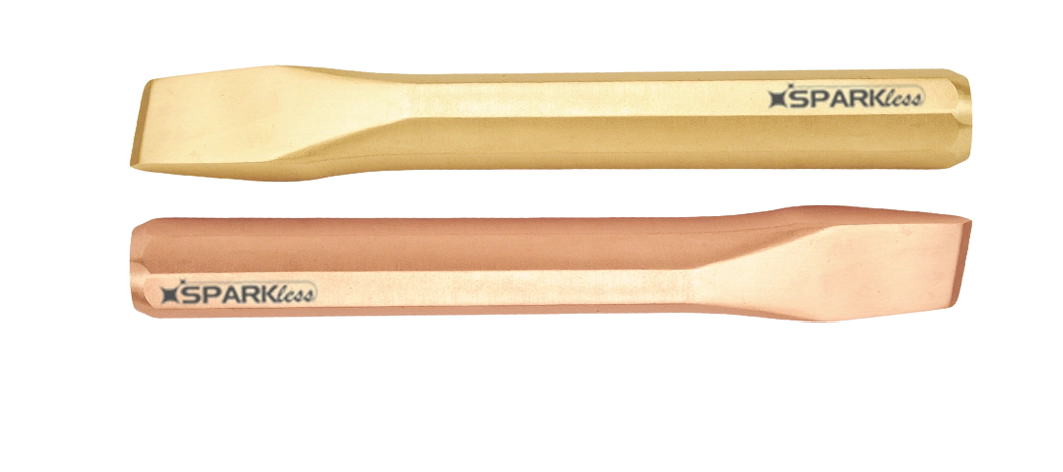

Non-Sparking AlBr Flat Chisel 200 mm

₹ 1,831.05 + 18% GST

-

non-sparking-albr-flat-chisel-200-mm-svec-1004a

Our Non-Sparking Flat Chisel is the best alternative to regular tools and finds application in potentially explosive environments.

Non-Sparking Tools are mandatory in any environment where an ignition source can result in a fire or explosion.

Our tools are tested and comply with IS 4595 standard for non-sparking properties.

- Non-sparking

- Good Hardness

- Corrosion Resistant

- Good Conductivity

- High Strenght

- Non-Magnetic

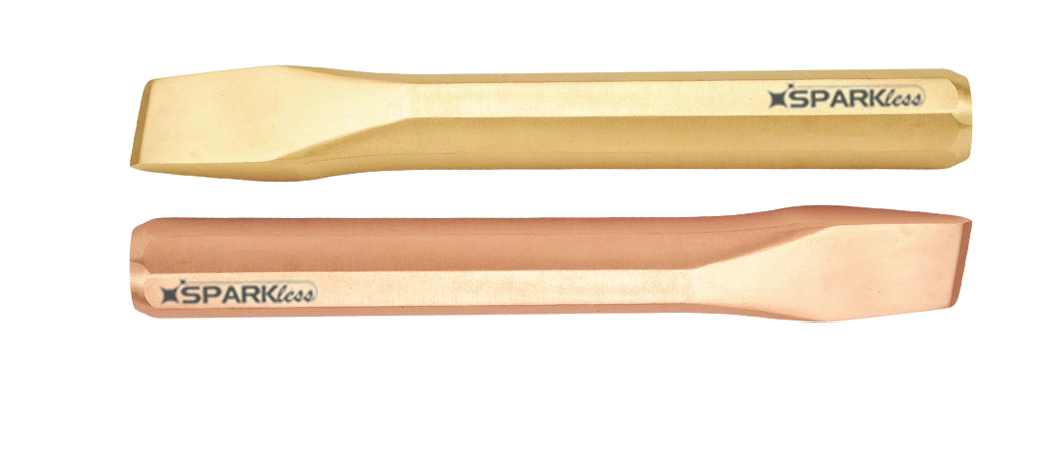

| Item Name | P/N | B mm | L mm |

| Flat Chisel | SVEC-1002 | 22 | 150 |

| Flat Chisel | SVEC-1004 | 22 | 200 |

| Flat Chisel | SVEC-1006 | 24 | 250 |

| Flat Chisel | SVEC-1008 | 25 | 300 |

| Flat Chisel | SVEC-1010 | 27 | 400 |

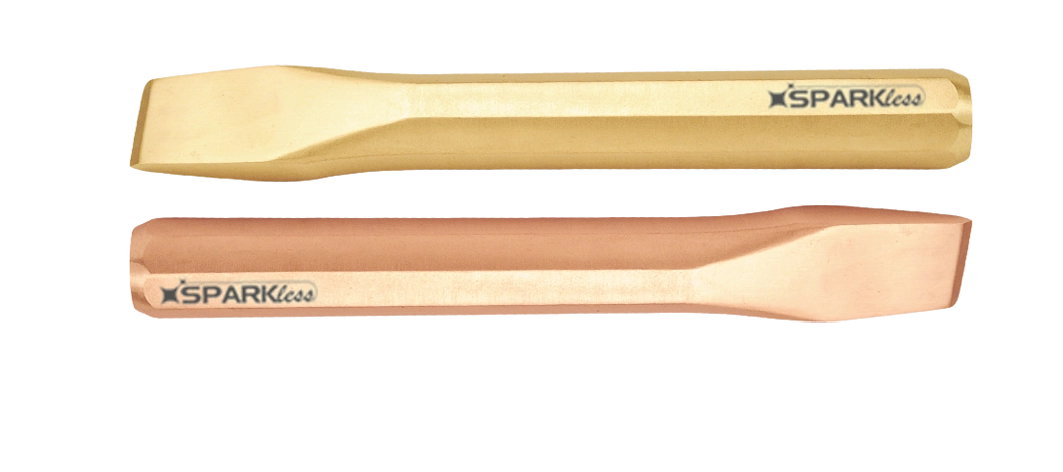

Mechanical Properties

We offer 2 kinds of materials for non-sparking tools,

Copper-Beryllium alloy (Be-Cu) and Aluminium-Bronze (Al-Br) alloy:

| COPPER-BERYLLIUM ALLOY | ALUMINIUM-BRONZE ALLOY | ||

| Composition | Be: 1.8%-2% Ni+Co: 0.2%-1.2% Others: <0.5% Rest: Cu | Composition | Al: 10%-12% Ni: 4 % – 6 % Fe+Mn: <5.8 % Others: <0.5% Rest: Cu |

| Hardness | 283-365 Brinell | Hardness | 229-291 Brinell |

| Tensile Strength | ~1250 N/mm2 | Tensile Strength | ~800 N/mm2 |

Removing scale from heat exchangers, cutting frozen bolts, chipping concrete around equipment foundations, and preparing surfaces for welding all require non-sparking chisels that won't ignite hydrocarbon vapors.

Non-sparking chisels experience extreme impact forces that could fracture brittle materials. Non-sparking alloys must maintain toughness to prevent tool fragmentation while eliminating spark generation during striking.

Guest December 28, 2024

Good quality non sparking tool.

Guest April 27, 2025

Tool meets industrial safety needs.

Guest May 01, 2026

Excellent product for explosive area applications.