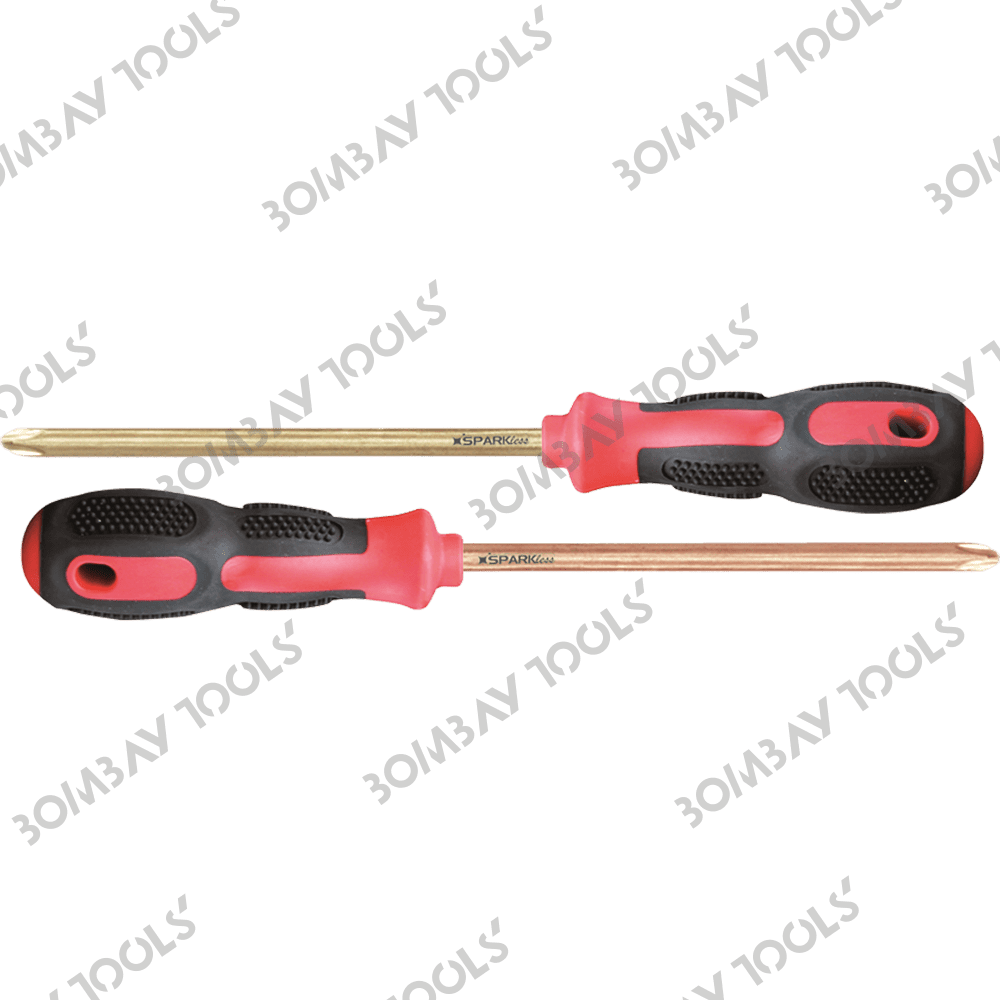

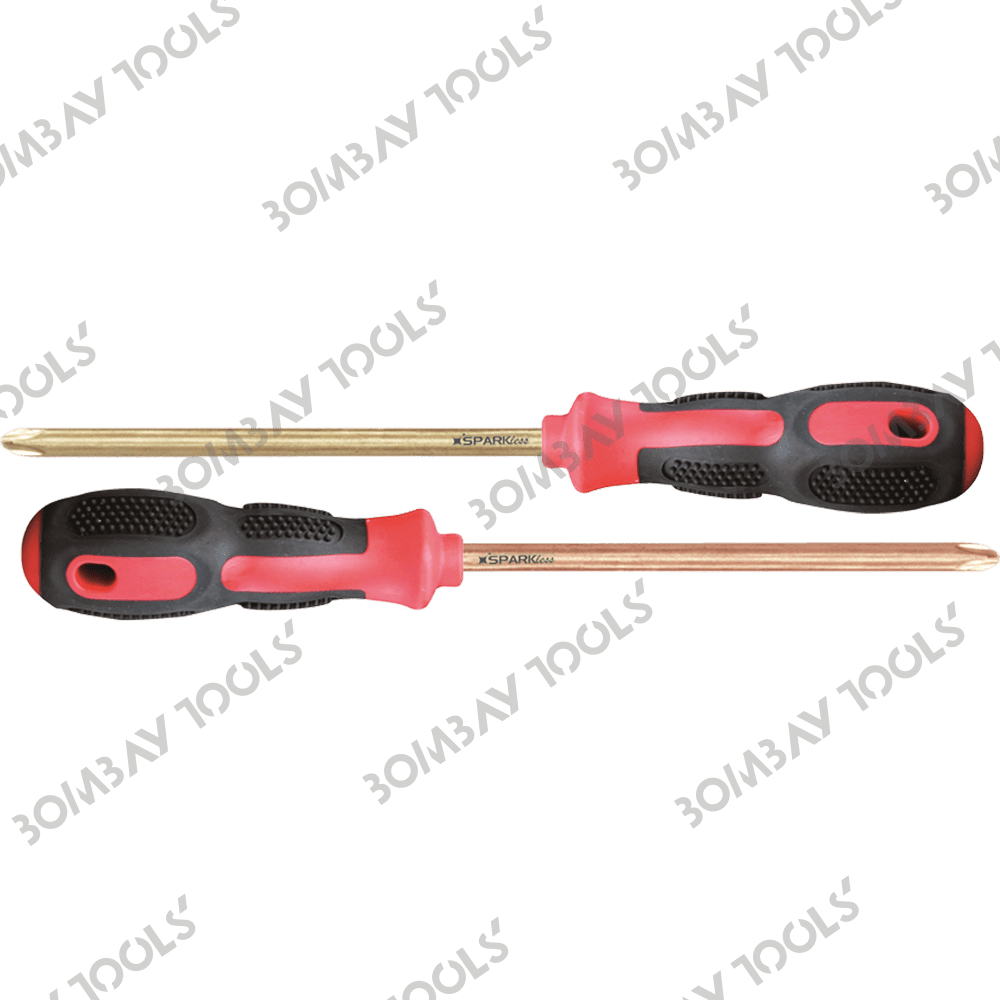

Non-Sparking AlBr Slotted Screwdriver 50*3mm

-

non-sparking-albr-slotted-screwdriver-50-3mm-szz-1002a

Our Non-Sparking Slotted Screwdriver is the best alternative to regular tools and finds application in potentially explosive environments.

Non-Sparking Tools are mandatory in any environment where an ignition source can result in a fire or explosion.

Our tools are tested and comply with IS 4595 standard for non-sparking properties.

- Non-sparking

- Good Hardness

- Corrosion Resistant

- Good Conductivity

- High Strenght

- Non-Magnetic

| Item Name | P/N | L1 inch | L1 mm | L mm | H mm | B mm |

| Slotted Screwdriver | SZZ-1002 | 2 | 50 | 134 | 0.4 | 3 |

| Slotted Screwdriver | SZZ-1004 | 2 | 50 | 134 | 0.5 | 4.5 |

| Slotted Screwdriver | SZZ-1006 | 3 | 75 | 159 | 0.4 | 3 |

| Slotted Screwdriver | SZZ-1008 | 3 | 75 | 159 | 0.5 | 4 |

| Slotted Screwdriver | SZZ-1010 | 3 | 75 | 180 | 0.6 | 5 |

| Slotted Screwdriver | SZZ-1012 | 4 | 100 | 184 | 0.5 | 4 |

| Slotted Screwdriver | SZZ-1014 | 4 | 100 | 205 | 0.6 | 5 |

| Slotted Screwdriver | SZZ-1016 | 4 | 100 | 215 | 0.8 | 6 |

| Slotted Screwdriver | SZZ-1018 | 5 | 125 | 240 | 0.8 | 6 |

| Slotted Screwdriver | SZZ-1020 | 6 | 150 | 265 | 0.8 | 6 |

| Slotted Screwdriver | SZZ-1022 | 6 | 150 | 265 | 1 | 7 |

| Slotted Screwdriver | SZZ-1024 | 6 | 150 | 277 | 1.2 | 8 |

| Slotted Screwdriver | SZZ-1026 | 8 | 200 | 327 | 1.2 | 8 |

| Slotted Screwdriver | SZZ-1028 | 10 | 250 | 377 | 1.4 | 9 |

| Slotted Screwdriver | SZZ-1030 | 10 | 250 | 377 | 2 | 11 |

| Slotted Screwdriver | SZZ-1032 | 12 | 300 | 427 | 1.8 | 10 |

| Slotted Screwdriver | SZZ-1034 | 12 | 300 | 427 | 2 | 11 |

| Slotted Screwdriver | SZZ-1036 | 14 | 350 | 477 | 2 | 11 |

| Slotted Screwdriver | SZZ-1038 | 16 | 400 | 550 | 2.4 | 12 |

Mechanical Properties

We offer 2 kinds of materials for non-sparking tools,

Copper-Beryllium alloy (Be-Cu) and Aluminium-Bronze (Al-Br) alloy:

| COPPER-BERYLLIUM ALLOY | ALUMINIUM-BRONZE ALLOY | ||

| Composition | Be: 1.8%-2% Ni+Co: 0.2%-1.2% Others: <0.5% Rest: Cu | Composition | Al: 10%-12% Ni: 4 % – 6 % Fe+Mn: <5.8 % Others: <0.5% Rest: Cu |

| Hardness | 283-365 Brinell | Hardness | 229-291 Brinell |

| Tensile Strength | ~1250 N/mm2 | Tensile Strength | ~800 N/mm2 |

Precisely machined tips on non-sparking screwdrivers provide secure engagement, maximize torque transfer, and prevent cam-out that damages fasteners. Quality tips remain sharp longer, reducing tool replacement costs.

Any industry where control panels, equipment covers, or instruments must be serviced in hazardous locations: petrochemical, pharmaceutical, food processing with combustible dust, and mining operations all require non-sparking screwdrivers.

.jpg)

Guest April 25, 2024

Non sparking characteristics are dependable.

Guest March 22, 2024

Good quality and compliant with safety norms.

Guest April 26, 2024

Meets safety requirements for hazardous area maintenance.