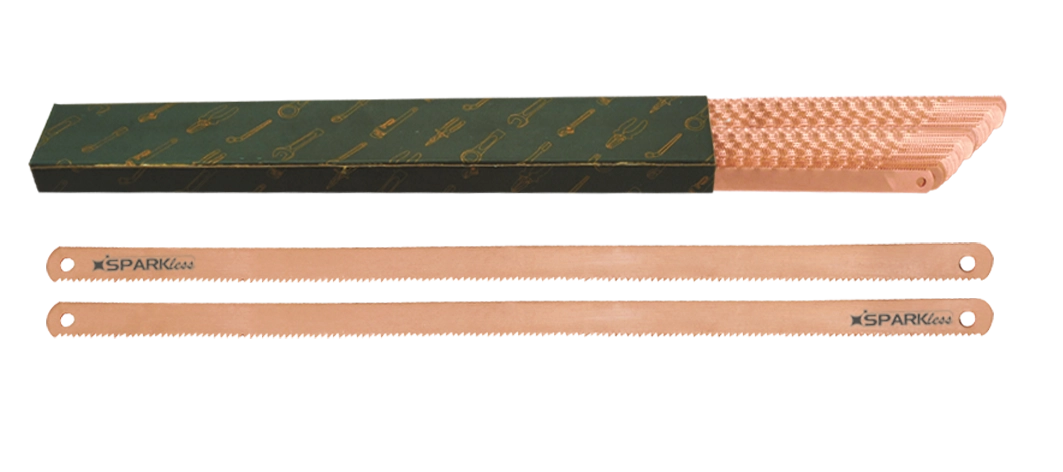

Non-Sparking BeCu Hacksaw Blade 300 mm

₹ 2,254.20 + 18% GST

-

non-sparking-becu-hacksaw-blade-300-mm-saa-1002b

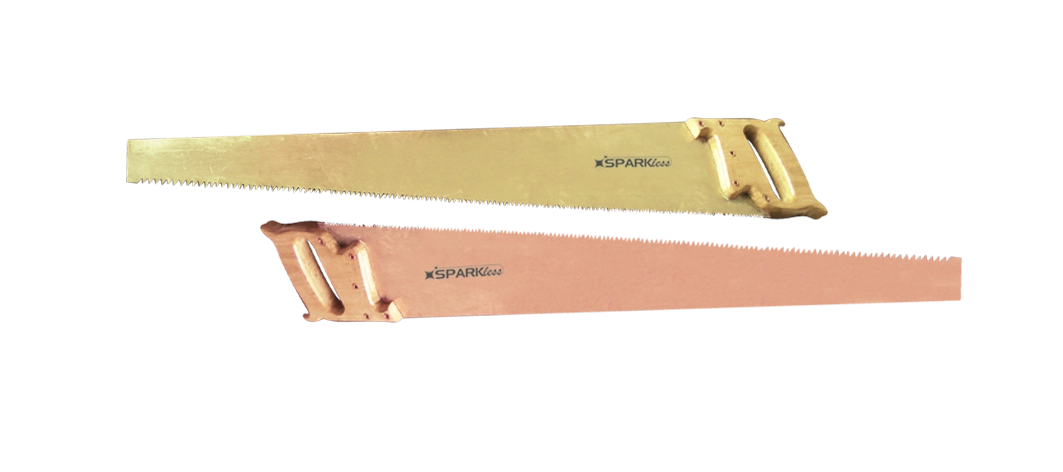

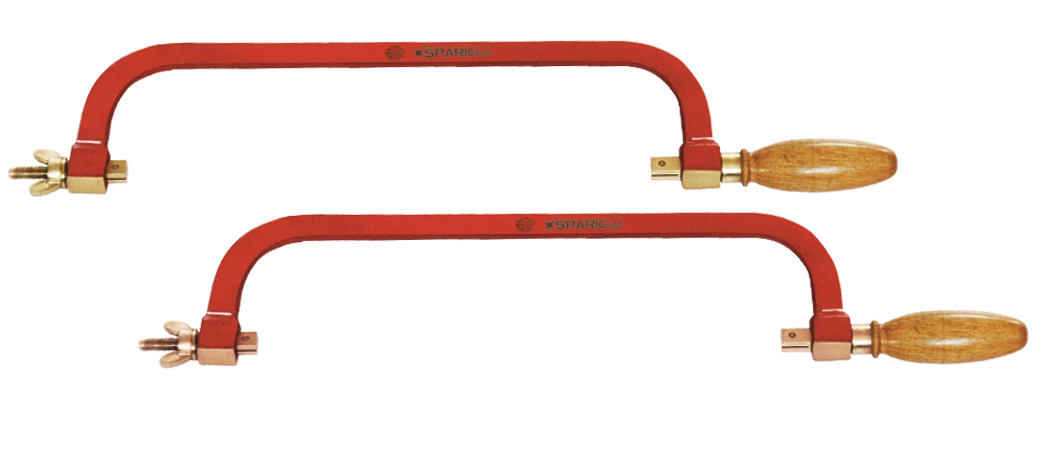

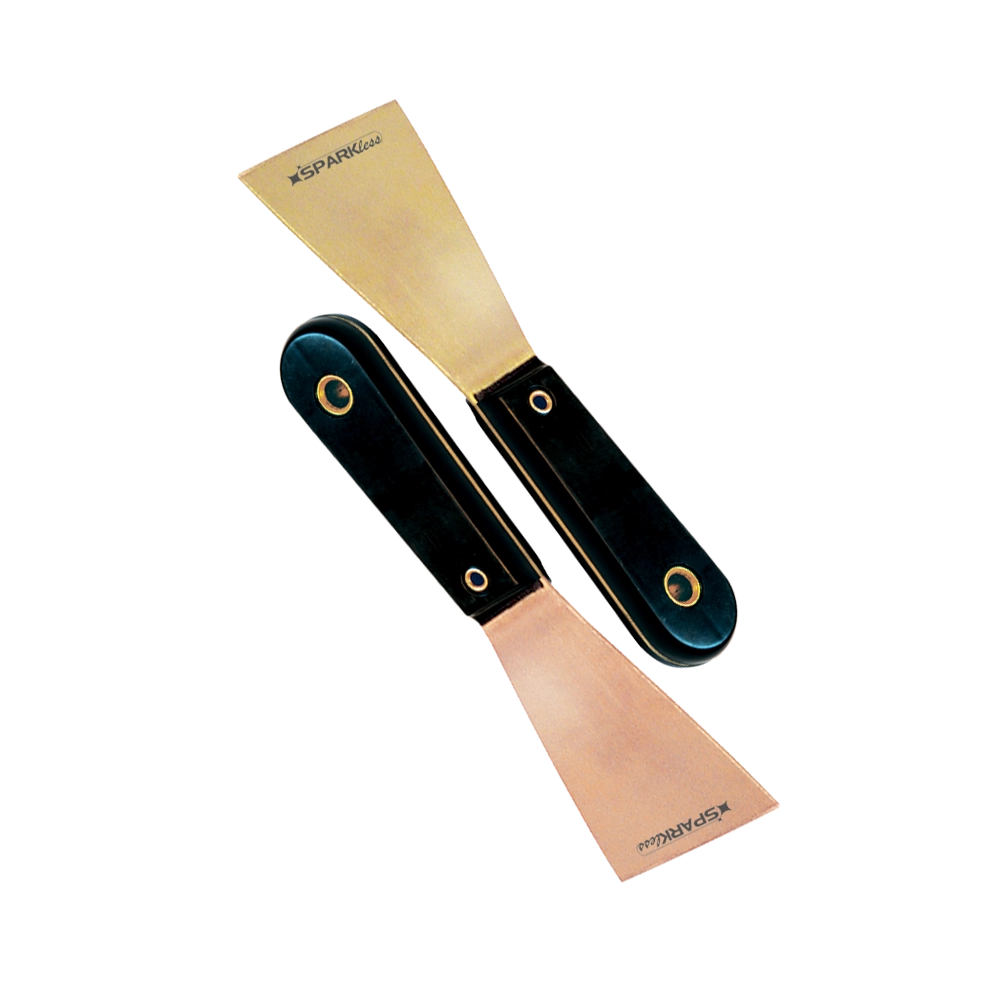

Our Non-Sparking Hacksaw Blade is the best alternative to regular tools and finds application in potentially explosive environments.

Non-Sparking Tools are mandatory in any environment where an ignition source can result in a fire or explosion.

Our tools are tested and comply with IS 4595 standard for non-sparking properties.

- Non-sparking

- Good Hardness

- Corrosion Resistant

- Good Conductivity

- High Strength

- Non-Magnetic

| Item Name | P/N | L mm | B mm |

| Hacksaw Blade | SAA-1002 | 300 | 12 |

Mechanical Properties

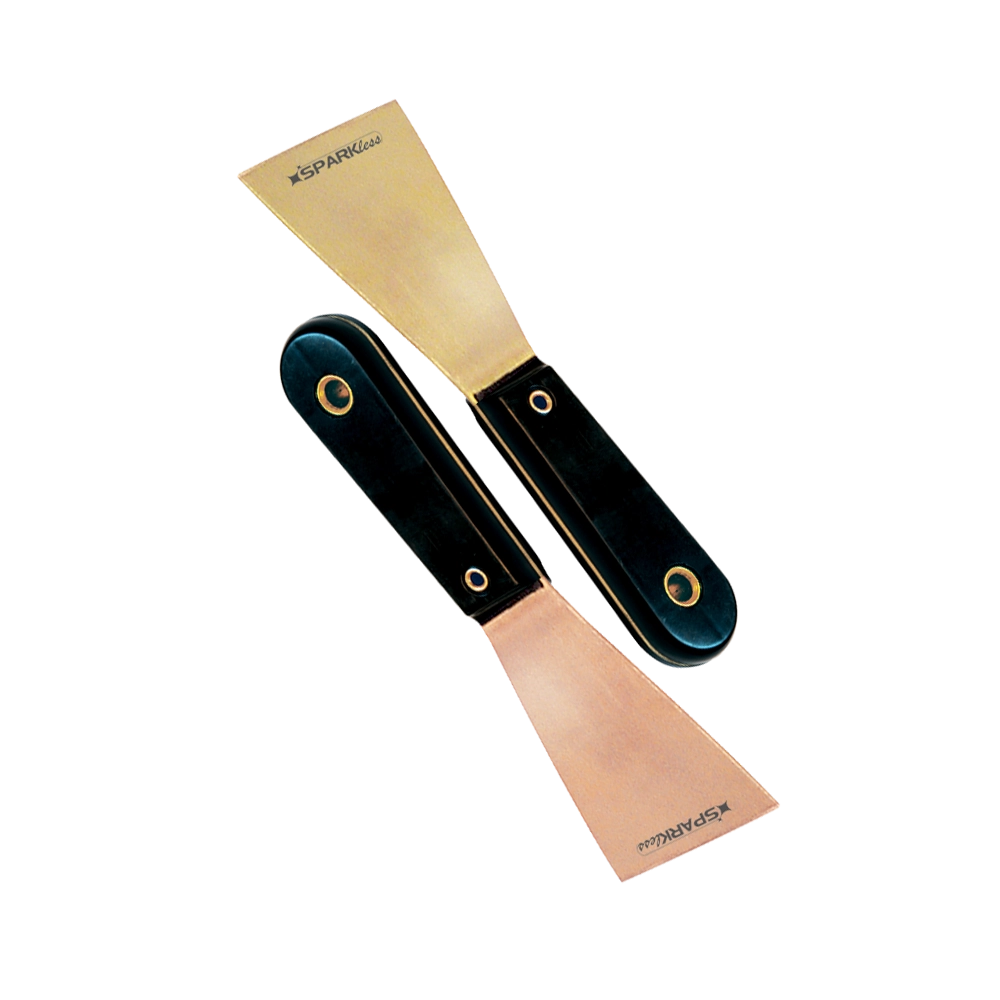

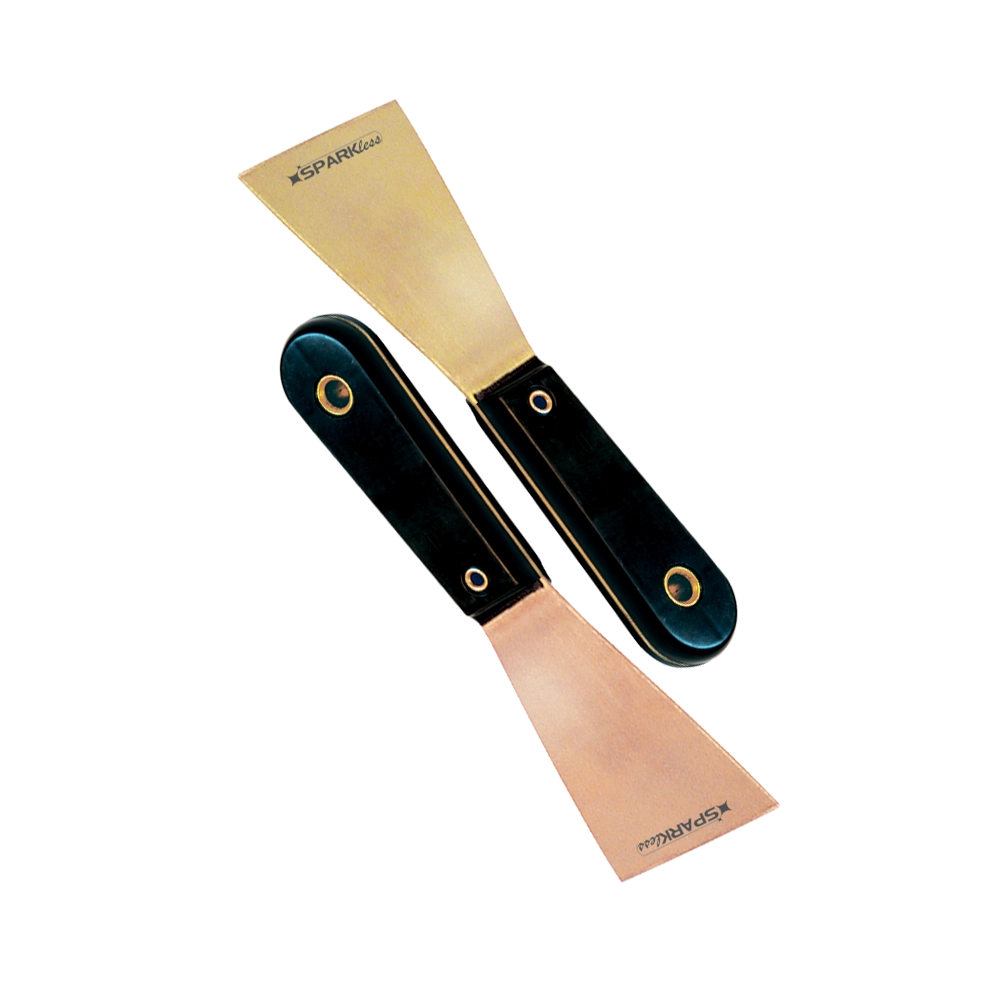

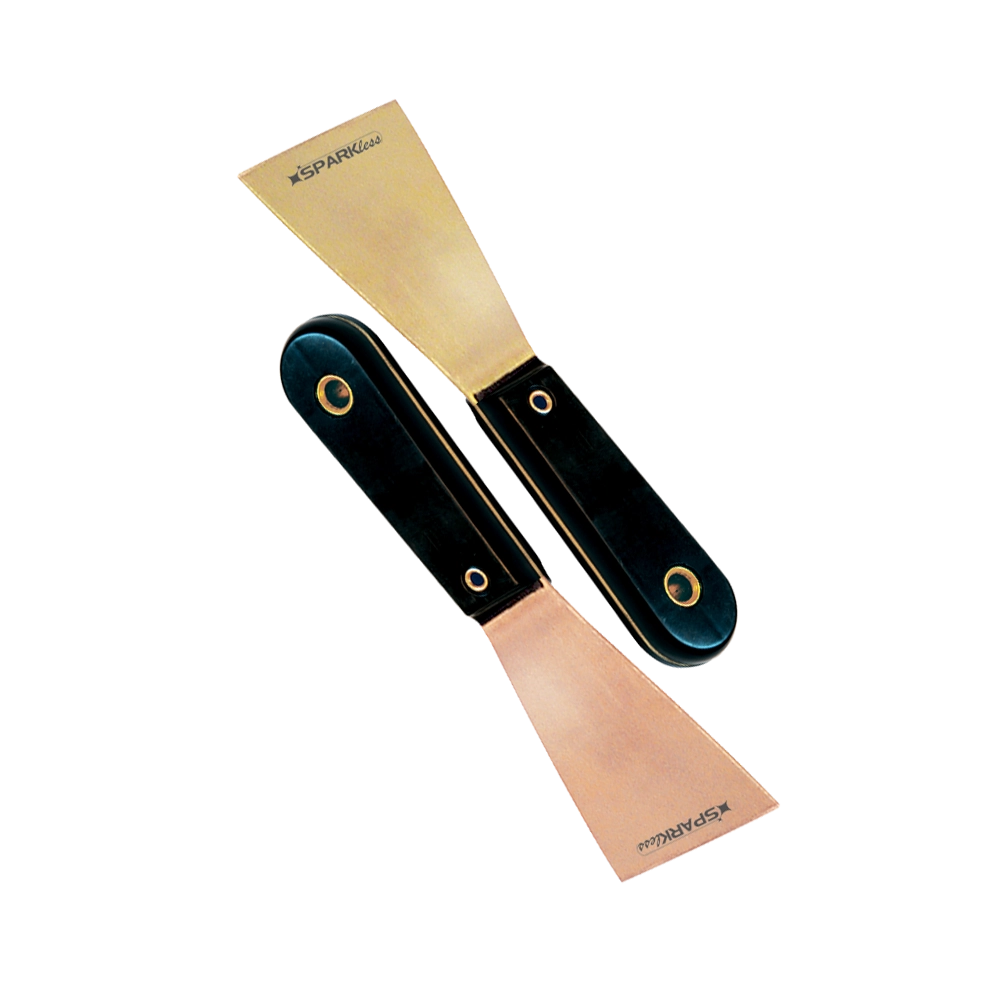

We offer 2 kinds of materials for non-sparking tools,

Copper-Beryllium alloy (Be-Cu) and Aluminium-Bronze (Al-Br) alloy:

| COPPER-BERYLLIUM ALLOY | ALUMINIUM-BRONZE ALLOY | ||

| Composition | Be: 1.8%-2% Ni+Co: 0.2%-1.2% Others: <0.5% Rest: Cu | Composition | Al: 10%-12% Ni: 4 % – 6 % Fe+Mn: <5.8 % Others: <0.5% Rest: Cu |

| Hardness | 283-365 Brinell | Hardness | 229-291 Brinell |

| Tensile Strength | ~1250 N/mm2 | Tensile Strength | ~800 N/mm2 |

These non-sparking blades cut through pipes, conduits, strapping, brackets, and various metals commonly encountered during repair and modification work in chemical plants, refineries, and mining facilities.

Tooth count and blade material determine cutting speed and surface finish. Proper non-sparking blade selection for the material being cut improves efficiency and blade life during maintenance operations.

Guest September 05, 2024

Works well for routine maintenance tasks.

Guest March 04, 2024

Good quality and compliant with safety norms.

Guest May 15, 2025

Suitable for hazardous work environments.