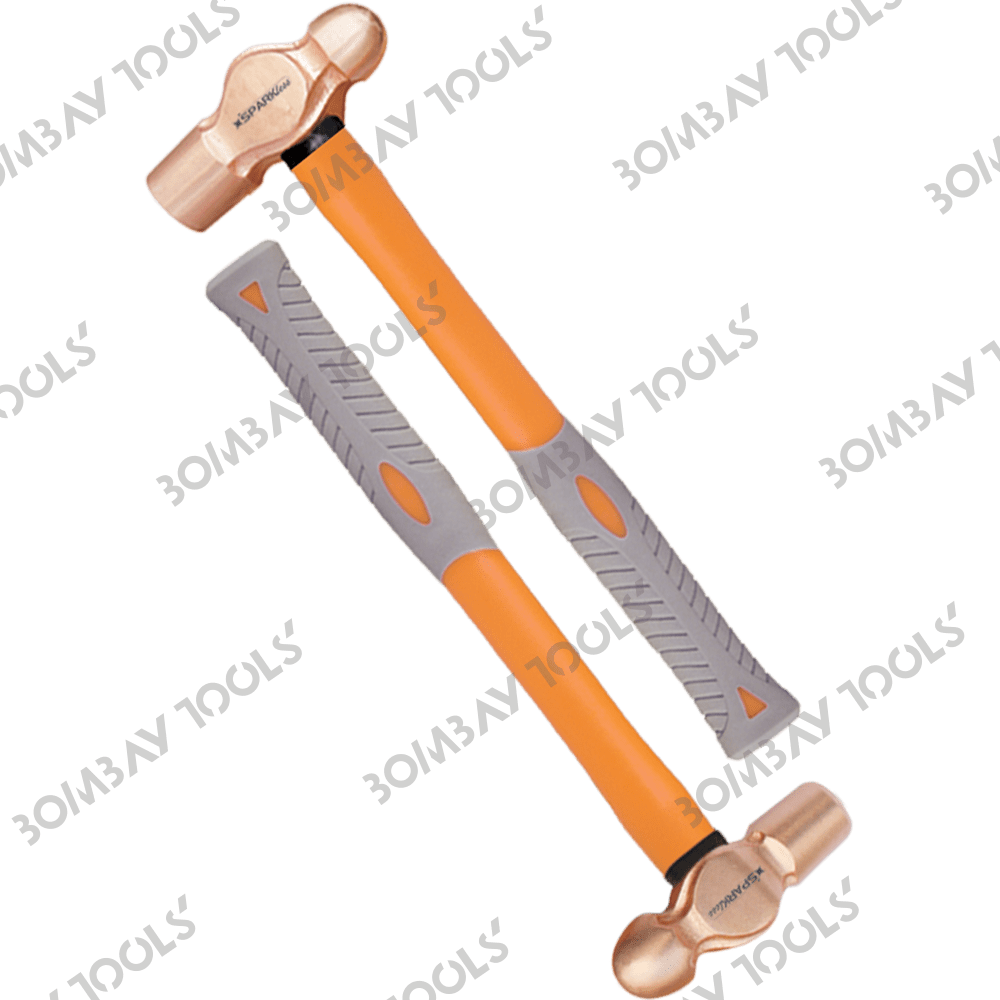

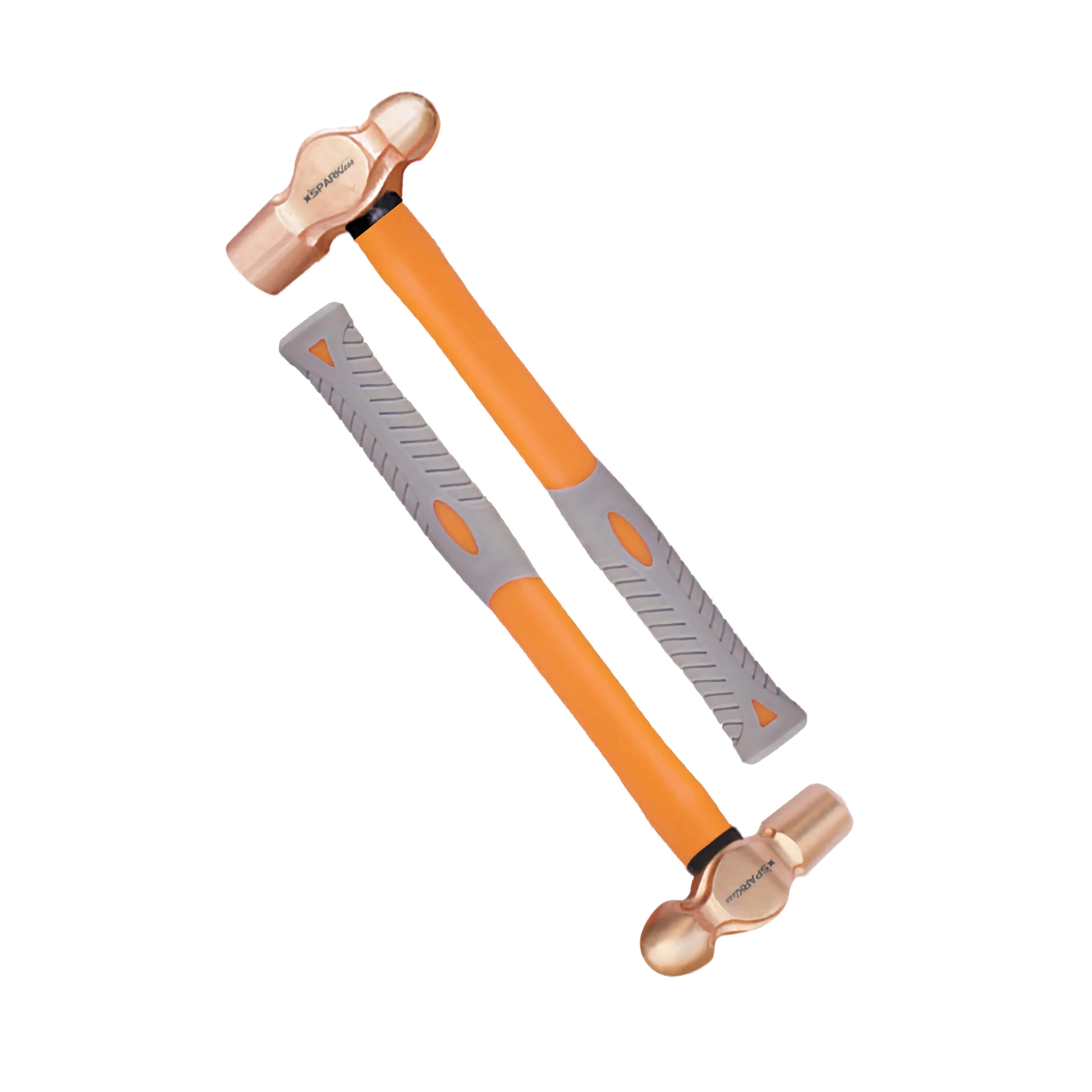

Non-Sparking AlBr Nylon Hammer 1000 g

₹ 4,598.75 + 18% GST

-

non-sparking-albr-nylon-hammer-1000-g-ssae-1004a

Non-Sparking Tools are Most Suited For Application Purposes In Potentially Explosive Environments.

Most of our Non-Sparking Tools are Forged after Casting to achieve better Quality, Performance & Attractive Finish.

| P/N | H g | L mm |

| SSAE-1002 | 800g | 340 |

| SSAE-1004 | 1000g | 400 |

Mechanical Properties

- Alloy: Aluminium-Bronze Alloy

- Composition

- Al: 10%-12%

- Ni: 4%-6%

- Fe Mn <5.8%

- Other: <0.5%

- Rest: Cu

- Hardness 25-30HRc (250-291 Brinell)

- Tensile Strength 800 N/mm 2

PROPER USE

- Claw hammers are intended for driving and pulling common, unhardened nails only, and for ripping apart wooden structures.

- They may be used to strike nail sets with the center of the striking face

ABUSE/MISUSE

- Never strike one hammer with or against another hammer or a hatchet.

- Never strike nail pullers, steel chisels, or other hardened objects with a claw hammer as the face may chip, possibly resulting in the eye or other serious injuries.

Different tasks require different impact forces and contact surfaces. Having appropriate non-sparking hammers prevents workpiece damage, improves efficiency, and reduces operator fatigue during maintenance operations.

Any striking operation in areas containing flammable vapors, combustible dust, or explosive materials requires non-sparking hammers. This includes maintenance in refineries, grain elevators, chemical plants, and munitions facilities.

Guest December 02, 2024

Suitable for chemical plant maintenance activities.

Guest June 02, 2026

Smooth finish and safe material.

Guest June 17, 2024

Works well in chemical and petrochemical plants.