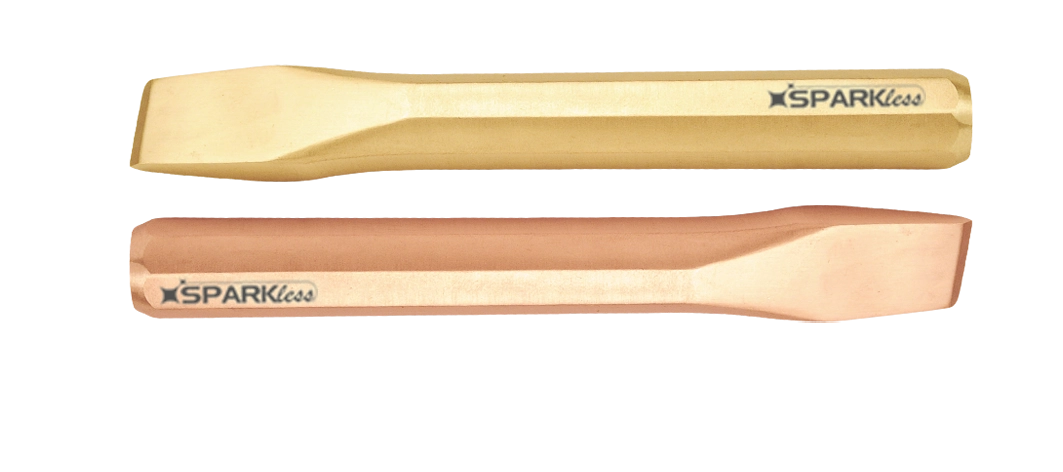

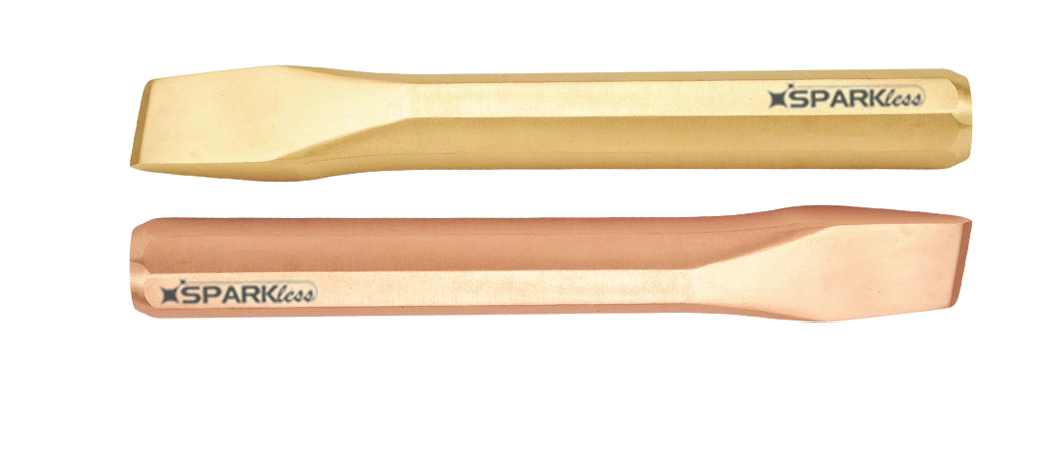

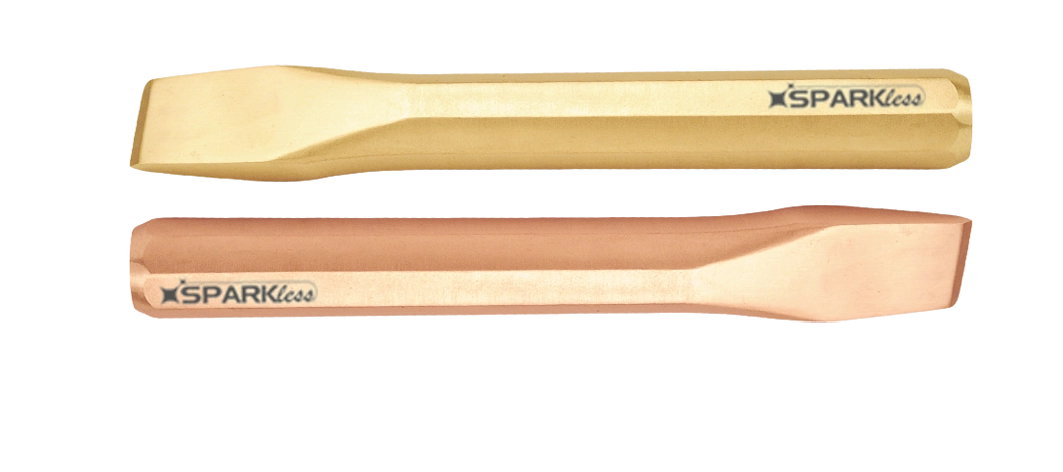

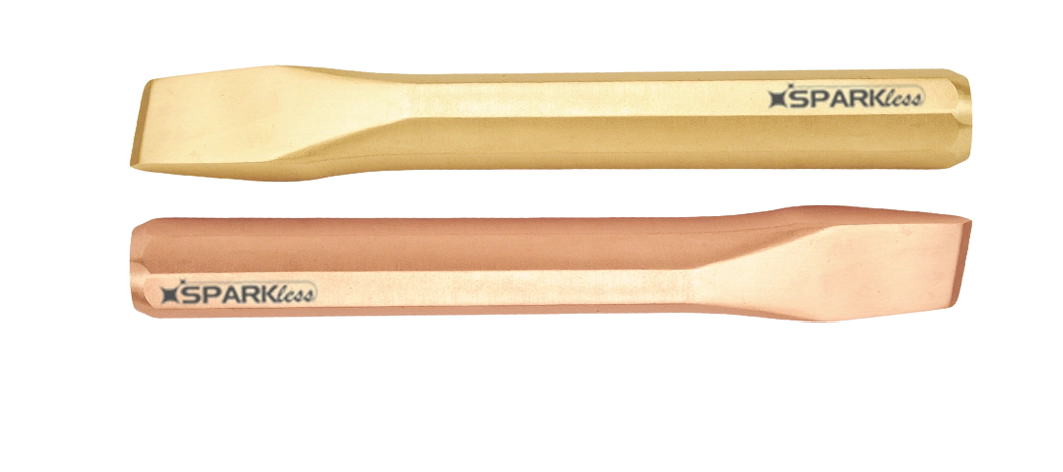

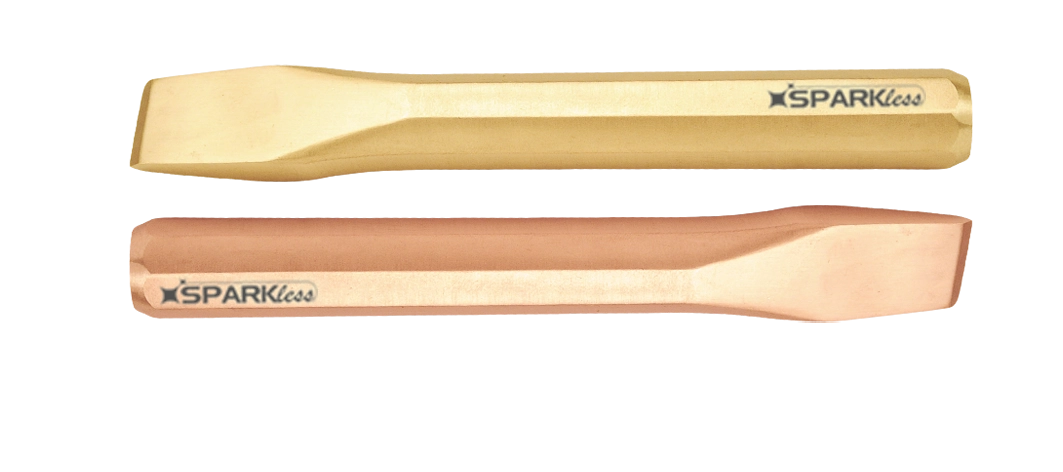

Non-Sparking AlBr Pneumatic Chisel 125 mm

-

non-sparking-albr-pneumatic-chisel-125-mm-svi-1002a

Our Non-Sparking Pneumatic Chisel is the best alternative to regular tools and finds application in potentially explosive environments.

Non-Sparking Tools are mandatory in any environment where an ignition source can result in a fire or explosion.

Our tools are tested and comply with IS 4595 standard for non-sparking properties.

- Non-sparking

- Good Hardness

- Corrosion Resistant

- Good Conductivity

- High Strenght

- Non-Magnetic

| Item Name | P/N | S mm | L mm | H mm | B mm |

| Pneumatic Chisel | SVI-1002 | 10 | 125 | 2 | 20 |

| Pneumatic Chisel | SVI-1004 | 10 | 175 | 2 | 20 |

Mechanical Properties

We offer 2 kinds of materials for non-sparking tools,

Copper-Beryllium alloy (Be-Cu) and Aluminium-Bronze (Al-Br) alloy:

| COPPER-BERYLLIUM ALLOY | ALUMINIUM-BRONZE ALLOY | ||

| Composition | Be: 1.8%-2% Ni+Co: 0.2%-1.2% Others: <0.5% Rest: Cu | Composition | Al: 10%-12% Ni: 4 % – 6 % Fe+Mn: <5.8 % Others: <0.5% Rest: Cu |

| Hardness | 283-365 Brinell | Hardness | 229-291 Brinell |

| Tensile Strength | ~1250 N/mm2 | Tensile Strength | ~800 N/mm2 |

Removing scale from heat exchangers, cutting frozen bolts, chipping concrete around equipment foundations, and preparing surfaces for welding all require non-sparking chisels that won't ignite hydrocarbon vapors.

Non-sparking chisels experience extreme impact forces that could fracture brittle materials. Non-sparking alloys must maintain toughness to prevent tool fragmentation while eliminating spark generation during striking.

Guest August 24, 2024

Good build quality and safe handling.

Guest February 18, 2024

Non sparking feature is reliable. Suitable for routine use.

Guest February 15, 2025

Strong and reliable tool for hazardous zones.